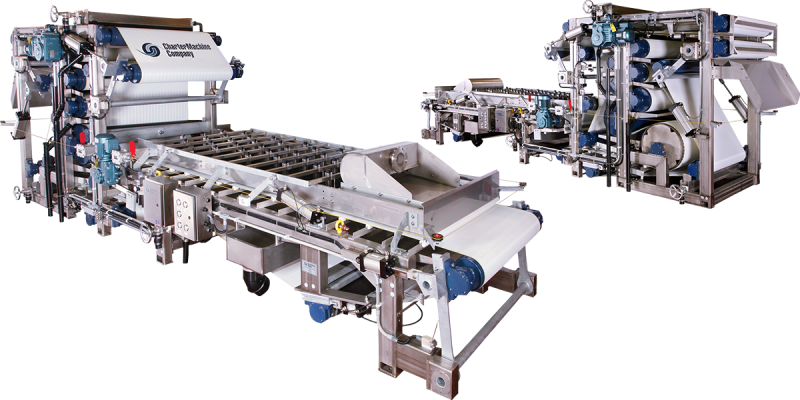

Sentry Press

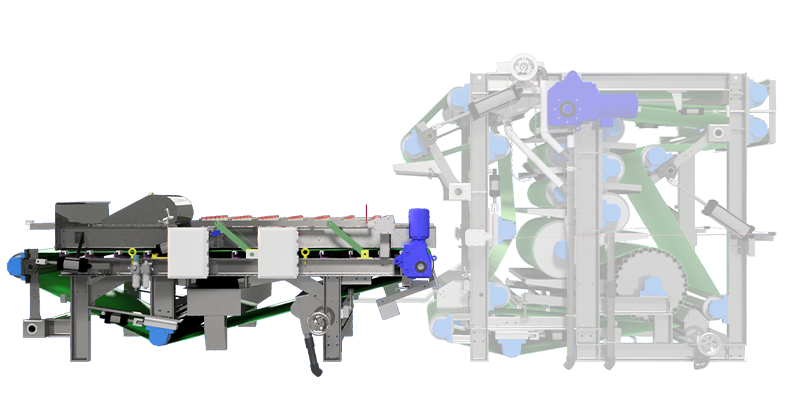

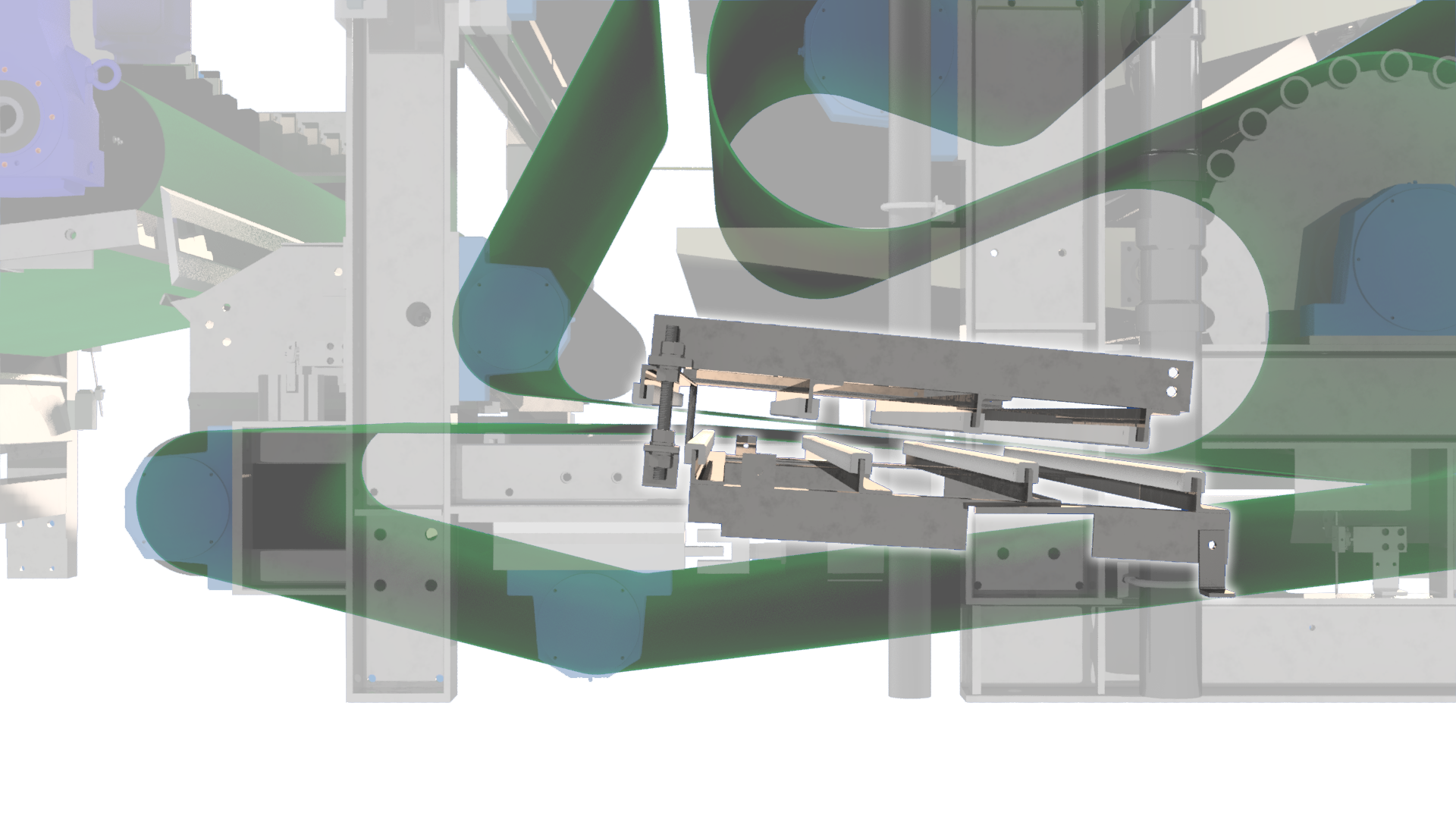

The Next Generation of 3-Belt Press

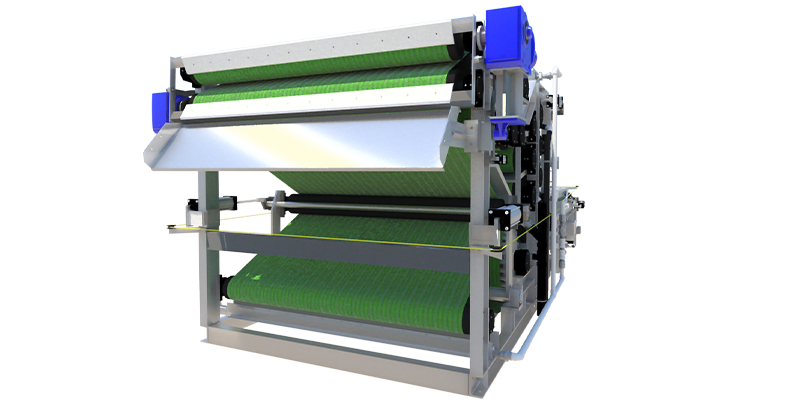

The Sentry Press achieves maximum dewatering output with its three-belt design and vertical pressure zone, efficiently processing large volumes of low-density materials, resulting in exceptionally dry cakes.

Product Data

Description

How It Works Is Innovative. How It Performs Is Amazing.

Charter Machine’s Model Sentry Three Belt Press has been engineered for paramount functionality to handle the highest flow rates at thin feed concentrations, providing maximum cake dryness. The Sentry Press combines its user friendly features, high quality construction, in house staff and support to contribute to lowering overall cost of operation.

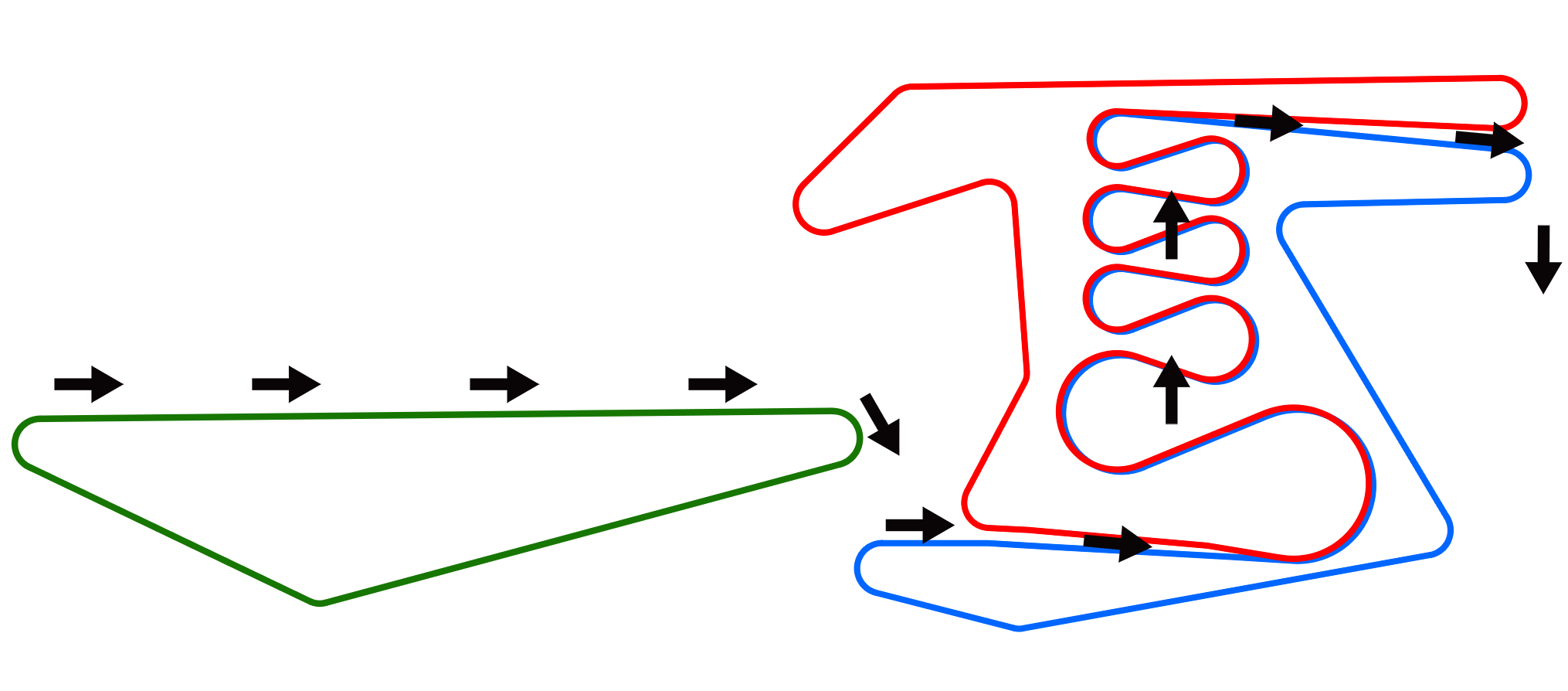

The Sentry Press incorporates the Tower Press arrangement, giving each pressure roll a minimum of 205-degree belt wrap, maximizing time under pressure. The Sentry Press has a 4-foot initial gravity deck for easy viewing. A belt drive and variable-frequency drive enable belt speed selection independent of the pressure section. This makes thin biosolids become more manageable and allows higher cake solids to be achieved. It's discharge point is more than six feet from the base to accommodate conveyors or auxiliary equipment. Belt alignment is maintained by a center-pivot design, minimizing belt stretch. Rilsan-coated one-piece pillow block housings with gasketed end plates house self-aligning double-roll spherical-type bearings with quadruple lip seals. Machined and polished shafts are held in place with a lock ring, eliminating slippage or misalignment. The low profile gravity zone, tubular or channel steel frame, open or enclosed frame design, and pneumatic or hydraulic operation all provide easier viewing, operation, and maintenance.

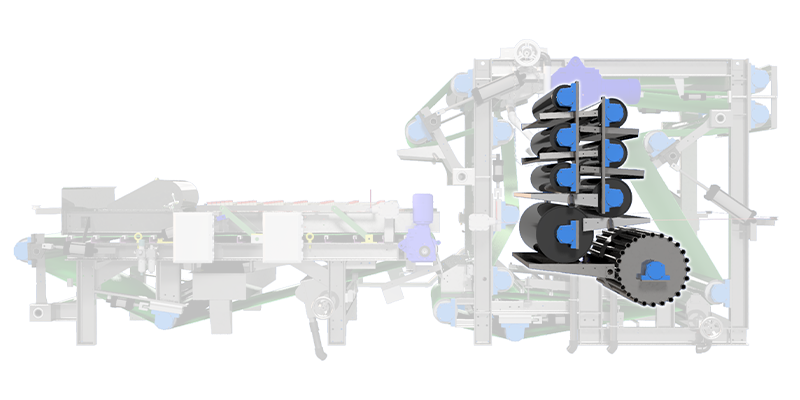

The Sentry Regent Press

The Sentry Regent 15 Roll High Solids Press is an enlarged version of the standard 8 roll Sentry Press but with 15 rolls for increased cake solids. The 7 additional rollers provide maximum retention time allowing for additional shearing and pressure. See our Sentry Regent Press page to discover how you can revolutionize your operations and embrace the future of belt filtration.

Models

| MODEL | # ROLLS | DECK STYLE | OAL | PLI | BELT WIDTH |

|---|---|---|---|---|---|

| 3BTP12.92S | 8 | SHORT | 21'-11 ¼" | 50 | 1.2 M |

| 3BTP12.93S | 8 | LONG | 23'-11 ¼" | 50 | 1.2 M |

| 3BTP17.92S | 8 | SHORT | 21'-11 ¼" | 50 | 1.7 M |

| 3BTP17.93S | 8 | LONG | 23'-11 ¼" | 50 | 1.7 M |

| 3BTP22.92S | 8 | SHORT | 21'-11 ¼" | 50 | 2.2 M |

| 3BTP22.92SH | 8 | SHORT | 21'-11 ¼" | 70 | 2.2 M |

| 3BTP22.93S | 8 | LONG | 25'-7 ⅜" | 50 | 2.2 M |

| 3BTP22.93SH | 8 | LONG | 25'-7 ⅜" | 70 | 2.2 M |

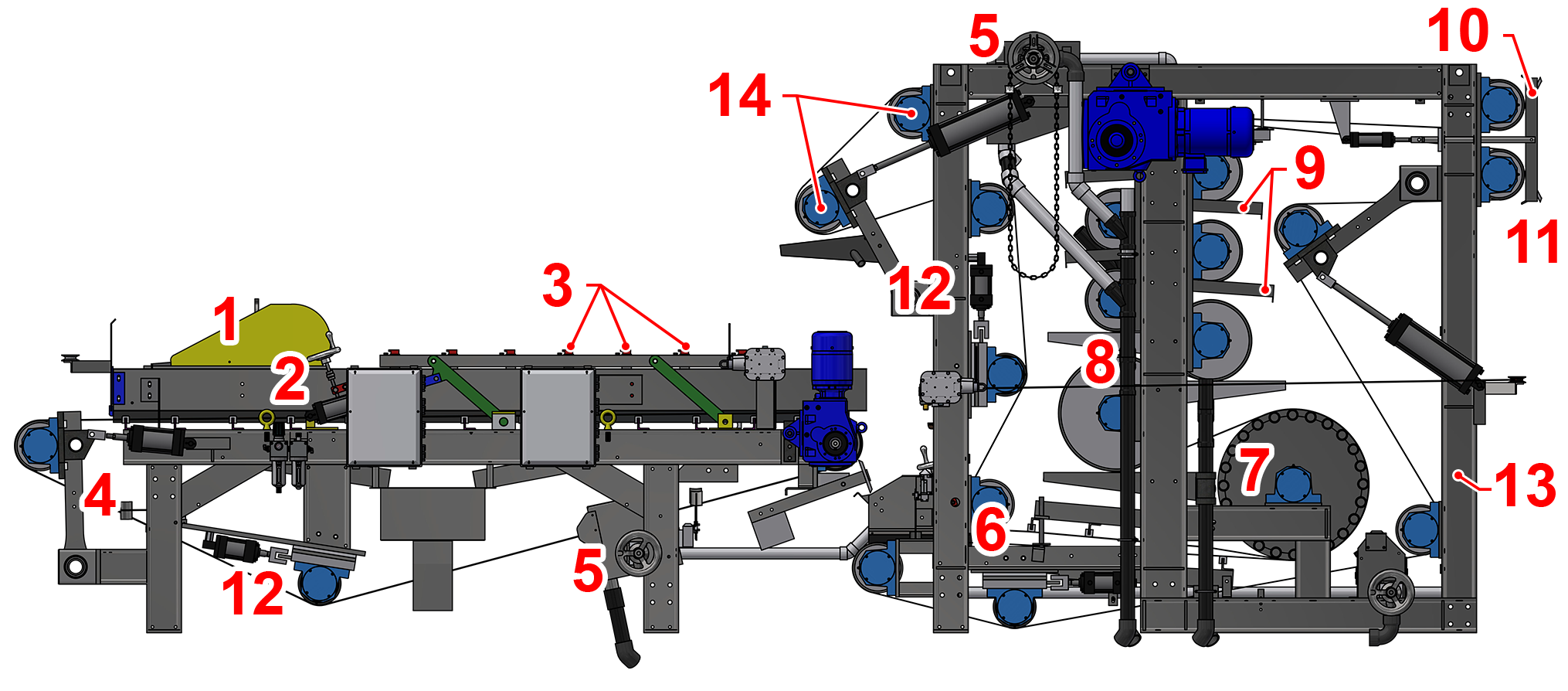

Features

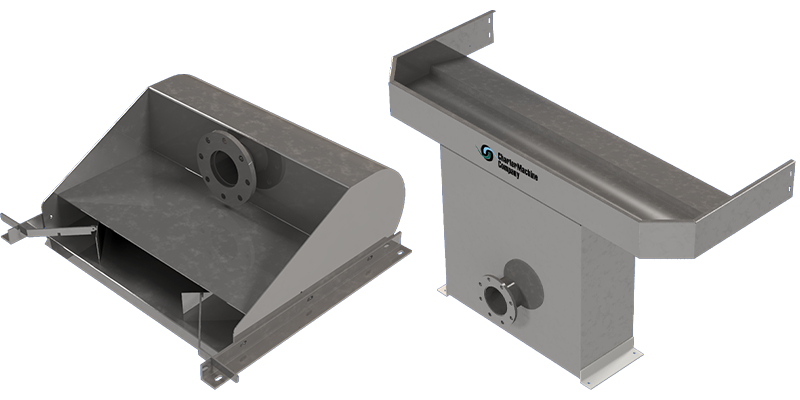

1. Feed Box - available in standard or upflow flocculation tank style.

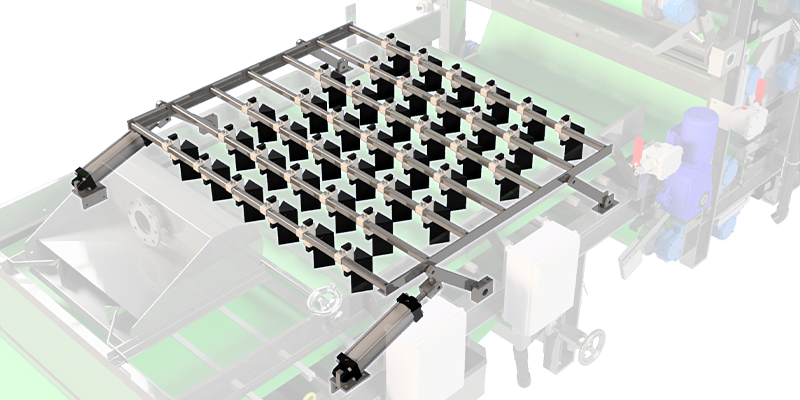

2. Independent Gravity Zone - fully automated independent Gravity Zone containing individually adjustable UHMW polyethylene plows free floating but properly weighted to always maintain contact with the belt. More rows and more plows increase belt exposure to allow filtrate to escape. Gravity zone portion of combined 3 belt unit can be lengthened or shortened to accommodate facility footprint or to suit process needs.

|

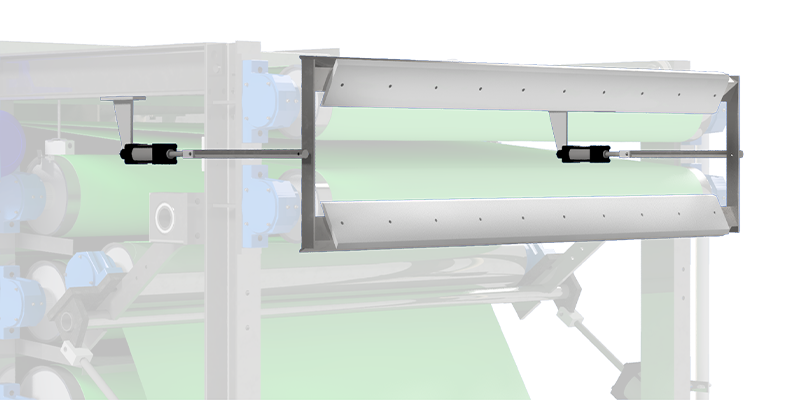

3. Plow Grid Assembly - Pneumatic / hydraulic actuator lifts or lowers the entire plow grid assembly for easier cleaning, eliminating manually lifting each row of plows. Each plow assembly can be easily lifted out with your hand and replaced within 1 second.

|

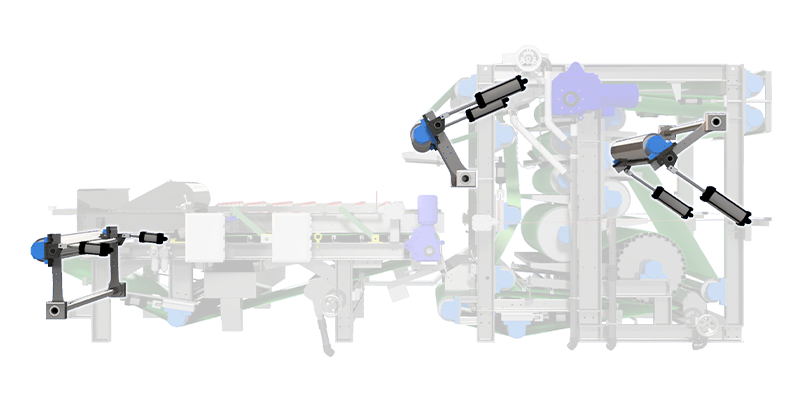

4. Rigid Tensioning Assembly - Pneumatic / Hydraulically controlled rigid tensioning assembly adjusts and maintains belt tension with parallel movement for extended belt life.

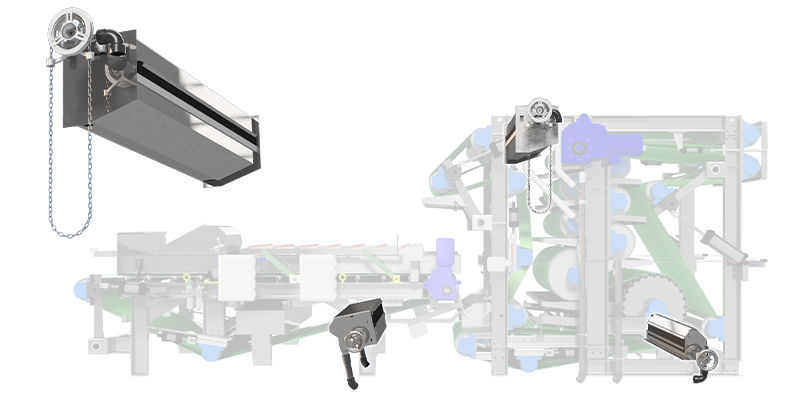

5. Belt Wash Station - Stainless steel belt wash station, internal brush system with hand-wheel operated flush design.

6. Adjustable Wedge Zone - Sentry Regent Press employs an adjustable wedge zone capable of providing positive pressure on both belts.

|

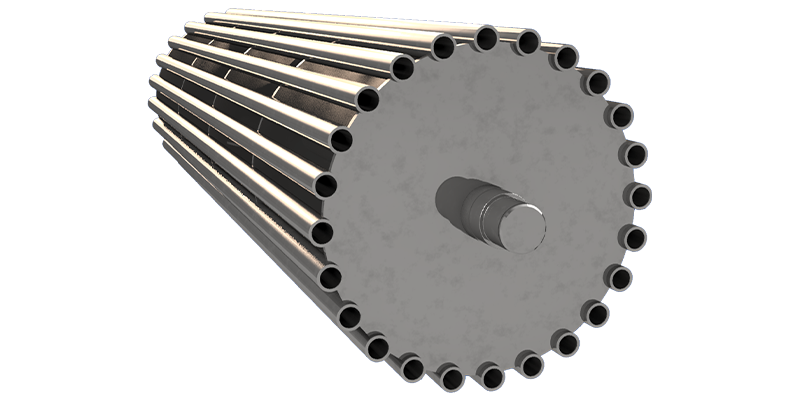

7. Maximum Efficiency Perforated Roll - Charter’s Perforated Roll is unique in its design in that it allows for more water to pass through the belt for better dewatering performance. With over 89% open surface area it leads the industry. The industry standard is only 33% opening or less.

|

8. Vertical Pressure Zone - Charter Machine Company incorporates our tower press arrangement of rollers into the Sentry design. This enables every pressure roll to have a minimum of 205-degree belt wrap, which maximizes time under pressure and guarantees high cake solids.

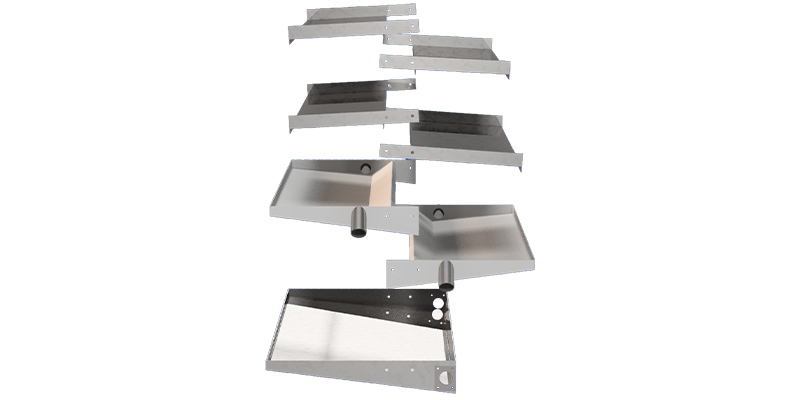

9. Individual Drain Pans - The Vertical Arrangement allows every drop of water removed by the belts to cascade through a series of stainless-steel drip pans positioned under each roller, which eliminates the rewetting of any sludge cake between the belts.

|

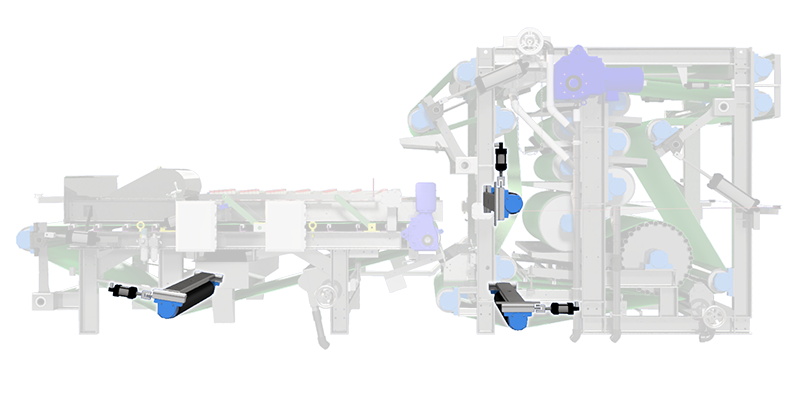

10. Automated Discharge Doctor Blade Retraction - Doctor blades are pneumatically / hydraulically actuated for easier operation and cleaning. Another great automation with just a flip of a switch, the cylinders push the doctor blades off the belts for easy cleaning and changing. Flip the switch again and the blades retract.

|

11. Elevated Discharge - The Sentry Regent Press features an elevated discharge that’s more than 6 feet from the base of the press frame making it easier to design, install and maintain conveyor.

|

12. Center Pivot Tracking - Charter is the only manufacturer in the industry to use center pivot steering. This means that when the belt is moving out of alignment, the controlling cylinder moves the roller to track the belt back. All other manufacturers use an end pivot which stretches out the belts since a movement of 4” would all be on one side as compared to center pivot that means each side of the belt only moves 2”.

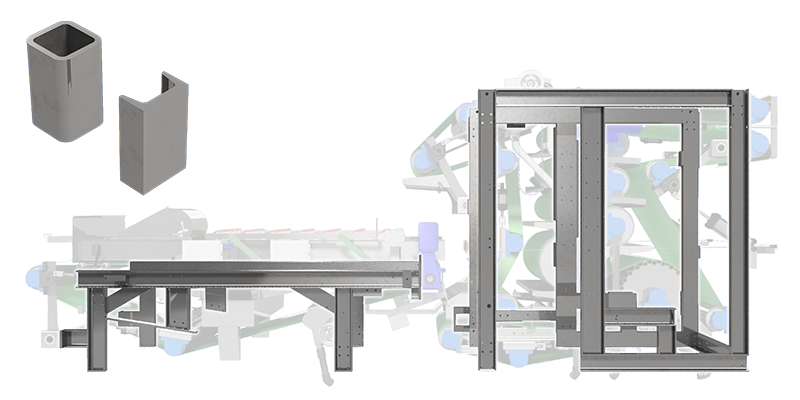

13. Tubular or Channel Frame Construction - the standard is hot-dipped galvanized to a minimum of 5 mil thickness. Tubular Frame or Channel Frame Construction is available in Carbon Steel, 304 or 316 stainless steel.

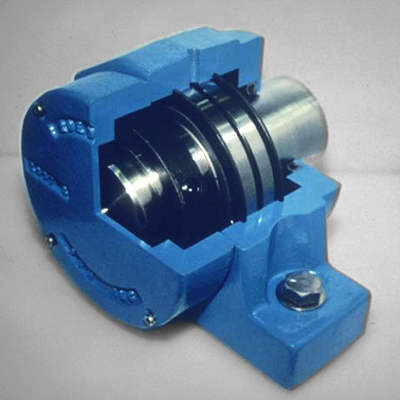

14. One Piece Bearing Housing - The Sentry Press utilizes a one-piece pillow block housing with a gasketed and bolted end plate. All bearings are self-aligning double roll spherical roller type and provided with quadruple lip seals. All shafts are machined and polished. Each shaft is held in place with a lock ring to guarantee alignment and eliminate any slippage or misalignment that can occur with other arrangements. All bearing housings are coated with a standard 20 mil thickness of Rilsan Nylon utilizing the electro static fusion bonding process. No place for rust to start.

|

Pneumatic or Hydraulic Design

Pneumatic or hydraulic control station capable of up to 70 pli design. The anodized aluminum cylinders with stainless steel shaft, tie rods, teflon seals and graphite bearings require no lubrication.

Benefits

Simplified Operation

- The gravity deck is positioned at eye level for effortless adjustments and seamless operation.

Reduced Costs

- The entire dewatering process may be observed from ground level, reducing plant design and construction costs. No platforms, catwalks, or complex conveyors needed.

- The Sentry Press easy maintenance, “hands-off” design reduces manpower hours and therefore overall operations costs.

- Maximum cake dryness achieved from our Sentry Presses results in hauling and land fill fee savings.

Maximum Performance

- Charter's three belt technology allows independent speed control regarding the gravity deck area versus the sheer/pressure zone. Thus, maximizing the units de-watering capability for the driest cake possible.

Enhanced Efficiency, Effortless Automation

- Doctor blades and plows are pneumatically actuated for easier operation and cleaning.

- Center pivot tracking rolls eliminate one-sided belt stretch and deliver quicker response to belt misalignment.

- Rigid tensioning assembly adjusts belt tensions with parallel movement.

- Optional filtrate recycling eliminates the need to use plant water to clean filter belts.

Improved Safety

- Easy access to Sentry Press at ground level minimizes fall risks.

- Corrosion can weaken structures and compromise safety. Using our non-corrosive equipment minimizes this risk of those operating in any around the vicinity. Charter strives to meet the needs of their clients whether it is the typical hot-dipped galvanized frame with stainless steel components or complete stainless-steel, 304, 316 S.S, models.

Design Flexibility

- Tubular or channel steel frame construction

- Open or enclosed frame design

- Pneumatic or hydraulic operation

- Feed box available in up-flow flocculation tank style

- Short and long gravity deck options available to accommodate facility footprint or to suit process needs.

- Hot-dipped galvanized, Carbon Steel, 304 or 316 stainless steel non-corrosive materials available

Multiple Sizes

- Sentry Press is sized to fit your needs. It’s available with a 1.2, 1.7 or 2.2-meter belt sludge dewatering equipment. Say goodbye to one-size-fits-all at Charter. We tailor our designs to fit your project like a glove.

Mix and Match, Plug and Play

- CMC offers skid mounted systems that can be customized to meet any facility's needs. Our sump/skid systems can include the belt filter press only or be a complete "plug and play" system combining any combination of sludge feed pump, compressor, booster pump, in-line mixer, polymer system, conveyors, and control panel. See our Skid-Mounted Systems page to discover the perfect combination of size and flexibility.

Video

Machine Drawings

Product Brochure

Related Products

Related Services

Image Gallery