Electro Osmosis Dehydrator

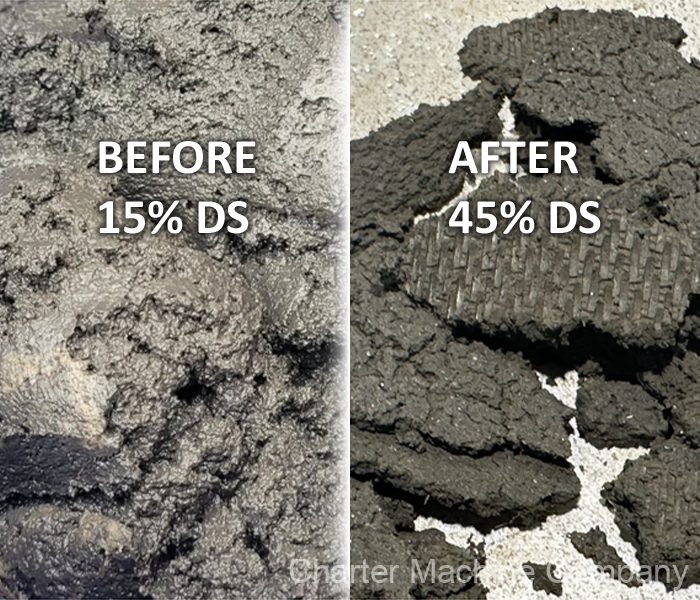

Reduce Sludge by 60% in just 3 minutes

ELODE is a Non-Thermal Sludge Dryer. ELODE uses electricity to drive water out of sludge on a molecular level rather than heat energy to evaporate water away, consuming 9x less energy to dewater sludge.

Product Data

Description

ELODE is used to dewater sludge cake using the lowest energy possible!

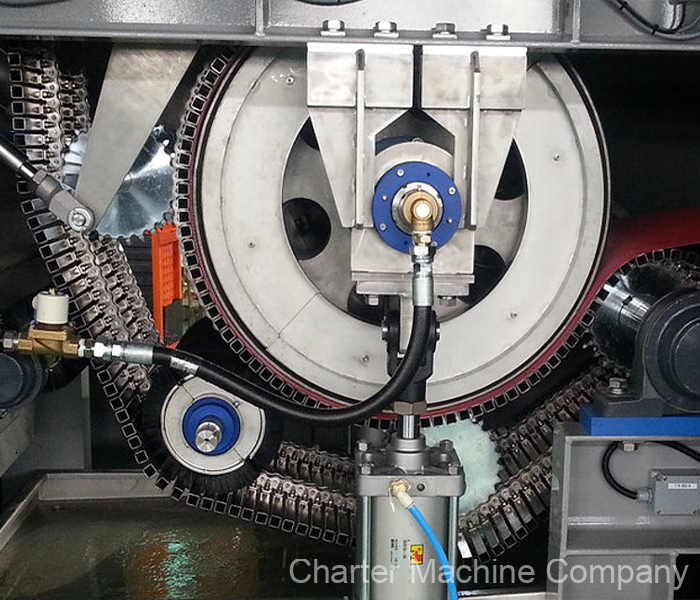

ELODE is 2nd stage dewatering machine made to further reduce water from sludge cake that has been dehydrated by other mechanical dewatering machines such as screw press, belt press, or centrifuge type of presses. ELODE takes the sludge cake in between two electrically charged surfaces where the Electro Osmosis Dehydrator (ELODE) instantly starts to pull moisture away from the sludge, resulting in a moisture level far below any mechanical means.

ELODE doesn’t need heat. ELODE harnesses the power of electricity and science!

Electro-osmosis is a chemical separation technique whereby a positively-charged liquid like water moves through a solid like sludge cake toward a negatively-charged cathode, when an electrical current is applied to create an electrical potential difference. ELODE uses electro-osmosis to drive water out of sludge on a molecular level rather than heat energy to evaporate water away, consuming 50% less energy to dewater sludge.

Drying by boiling water away by heat is incredibly inefficient!

Did you know evaporating water uses 9x the energy compared to heating it up to boil? Also, if you have a boiler or furnace for the dryer there is always wasted hot gas that goes out the stack, further exacerbating the overall energy inefficiency. Trying to heat sludge itself is like running a marathon to get to the starting line.

Save valuable time.

ELODE operates far below the boiling point of water (212°F), typically within the range of 158°F to 176°F. No more wait for heat transfer and even less wait for last the batch to exit the dryer at the end of day. Some thermal dryers take 6 hours for this, it is a waste of energy and time.

The Numbers are Stark.

See graph below showing the energy required to heat 1 Kg (2.2lbs) of water in various methods. The numbers tell it all, boiling water for drying is a massive energy guzzler.

Models

| MODEL | EODS-500 | EODS-1000 | EODS-2000 | EODS-3000 |

|---|---|---|---|---|

| Belt Width | 0.5 m | 1 m | 2 m | 3 m |

| Input Voltage | 3 phase, 220, 380, 480 VAC | |||

| Output DC Voltage | 30-90 VAC | |||

| Power Consumption (typical) | 40 KW | 70 KW | 120 KW | 180 KW |

| Input Sludge Typical Weight | 440-660 lb/hr | 880-1,300 lb/hr | 1,760-2,400 lb/hr | 2,600-3,500 lb/hr |

| Input Sludge Thickness | 6-10 mm | |||

| Input Sludge Typical DS | 10-35% from Mechanical Processes | |||

| Output Cake Typical DS | 40-50%, max 70%+ observed | |||

| Typical Belt Speed | 1.2 m/min | |||

| Typical Washer Water Use | 3 gal/min | 5 gal/min | 8 gal/min | 11 gal/min |

| Compressed Air Use Max | 1 gal/min | |||

| Sludge Conductivity Range | 2,000-10,000 uS/cm | |||

| Base Unit Dimension LxWxH | 3.2 x 1.9 x2.5 m | 3.2 x 2.5 x 2.5 m | 3.2 x 3.5 x 2.5 m | 3.2 x 4.5 x 2.5 m |

| Weight (kg) | 3,000 kg | 4,000 kg | 5,500 kg | 7,000 kg |

| Power Supply and Controller | 1.0 x 1.0 x 1.8 | 1.2 x 1.2 x 1.9 kg | 1.3 x 2.0 x 1.9 m | 1.3 x 2.8 x 1.9 m |

| Weight (kg) | 1,200 kg | 1,500 kg | 2,000 kg | 2,500 kg |

Benefits

Reduced Sludge

- Lower Disposal Cost

- Less Sludge Trucking

- Easier Handling (Almost Dry to the Touch)

- Excellent ROI

Low Energy

- Low Energy Used

- No Chemical Use

- Easier Burning Cake Produced

- Fast Cycle Time

- Quick Startup & Shutdown

- Excellent ROI

Compact Machine

- Super Heavy Gage Stainless-Steel Construction

- Low Line Speed, Continuous Cycle, Quiet

- Low Maintenance & Takes Little Space

- Almost No Heat Produced

- Easy Retrofit to Existing Dewatering Equipment

Reduced Odor

- Significant Odor Reduction

- Reduced Pathogens

- More Acceptable for Landfill

- Higher Sustainability

ELODE Advantage Over Heat Dryers

- Super Low Installation and Construction Cost

- No Huge Drying Conveyor Ovens

- No Exhaust Stack

- No Exterior Hot Heat Exchanger

- No Cyclone Dust Separator

- No Additional Odor Treatment (if already in place)

- No Large Blower Motor & Assembly

- No Duct Work Connecting all the above

- No Pellet Cooler at the Dryer Exit

- No Steam Condensers (huge water supply needed by this operation)

- Fraction of Heat Energy Used

- No Boiler, Furnace, or Compressors

- No Greenhouse Gas Produced

- No Dust Filters, No Fins to Clean

- No Fume/Dust Scrubber

- No Demister

- No Dust Issues

- No Extra Drain, Piping & Electrical Work

- ELODE is a Stock Unit

Applications

Typical Applications

|

|

Video

Product Brochure

Related Products

Related Services

Image Gallery