BP 6000

Tradition and Performance

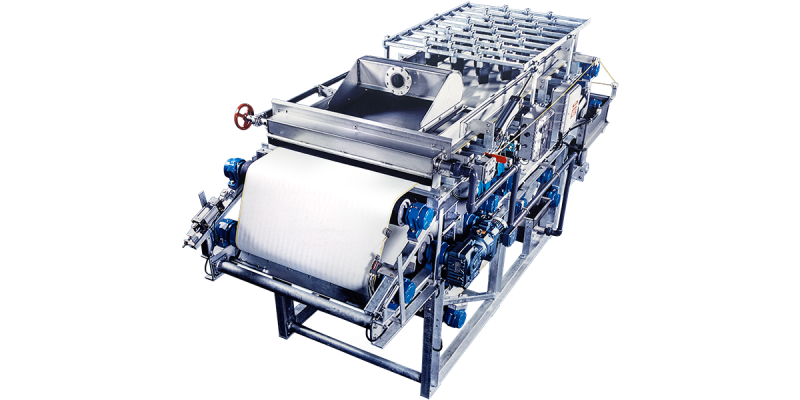

The BP6000 Series reimagines the traditional horizontal belt filter press. Built for unwavering strength and resilience, it boasts industry-leading moment of inertia (frame strength), safety factors, and minimal deflections, ensuring maximum performance and operator peace of mind.

Product Data

Description

This machine is the most economical, one of the smallest footprints. This is for users not as concerned about solids and performance, the BP6000 gets the job done. It’s the lowest cost model.

The BP6000 is most comparable to other belt filter presses, it’s a worldwide known standard style of the belt filter press. It is known throughout the world for its base-level performance and setting the standard. This is one of the most highly recognized belt filter presses that you’d be familiar with. In addition to the standard size horizontal press, we also offer a short-deck model for the shorter footprint but still maintain all the features and benefits of the original model. Charter strives to meet the needs of their clients whether it is the typical hot-dipped galvanized frame with stainless steel components or complete stainless-steel models. Our BP 6000 system can be the ideal solution for your sludge water dewatering needs.

BP6000 HS (12 Roll) Belt Press

Our BP6000 HS (High Solid) 12 Roll is an enlarged version of the BP6000. Four additional rollers (12 total) provide more retention time, allowing for additional shearing and pressure. Depending on the solids processed, this could increase cake solids by 2 to 5 percent.

Models

| MODEL | # ROLLS | DECK STYLE | OAL | PLI | BELT WIDTH |

|---|---|---|---|---|---|

| BP12.31 | 3 | SHORT | 16’-8 ¾” | 50 | 1.2 M |

| BP17.31 | 3 | SHORT | 16’-8 ¾” | 50 | 1.7 M |

| BP22.31 | 3 | SHORT | 16’-8 ¾” | 50 | 2.2 M |

| BP12.61 | 8 | SHORT | 16’-8 ¾” | 50 | 1.2 M |

| BP12.63 | 8 | LONG | 20’-8 ¾” | 50 | 1.2 M |

| BP17.61 | 8 | SHORT | 16’-8 ¾” | 50 | 1.7 M |

| BP17.63 | 8 | LONG | 20’-8 ¾” | 50 | 1.7 M |

| BP22.61 | 8 | SHORT | 16’-8 ¾” | 50 | 2.2 M |

| BP22.63 | 8 | LONG | 20’-8 ¾” | 50 | 2.2 M |

| BP22.63.12 | 12 | LONG | 20’-8 ¾” | 50 | 2.2 M |

Features

Center Pivot Tracking

Charter Machine utilizes a Pneumatic / Hydraulic controlled center pivot alignment system. This design reduces belt stretching, lengthens belt life and provides a more consistent performance over the life of the belt.

Belt Tensioning

Pneumatic / Hydraulically controlled rigid tensioning assembly adjusts and maintains belt tension with parallel movement for extended belt life.

One Piece Bearings

Charter Machine utilizes Rilsan Nylon coated one-piece solid pillow block bearing housings with gasketed end plate. Self-aligning double-row spherical bearings with quadruple lip seals. The contact surface of the shafts shall have a 60 micrometer polished finish to increase seal life and each stub shaft shall be held in place with a lock ring to guarantee alignment.

Plow Grid

Pneumatic / Hydraulic actuator lifts or lowers entire plow assembly for easier cleaning, eliminating systems manually lifting each row of plows. Plows “float” on belt and can be replaced without the use of tools.

Benefits

Reduced Costs

- Low polymer and power consumption

Maximum Performance

- Superior solids capture ratio

Low Maintenance, Streamlined Operation

- Pneumatically actuated sludge plow assembly

- Interchangeable spherical roller bearings

Sustainable, Non-Corrosive Construction

- Increased lifespan: Charter strives to meet the needs of their clients whether it is the typical hot-dipped galvanized frame with stainless steel components or complete stainless-steel, 304, 316 S.S, models. These non-corrosive materials last longer, reducing maintenance costs and replacement needs.

- Improved safety: Corrosion can weaken structures and compromise safety. Using our non-corrosive equipment minimizes this risk of those operating in any around the vicinity.

- Enhanced aesthetics: Many non-corrosive materials have a clean and modern appearance, contributing to the overall aesthetics of a project.

- Environmental benefits: Corrosion can lead to the release of harmful chemicals into the environment. Using non-corrosive materials reduces this risk and promotes sustainability.

Multiple Sizes

- BP6000 is sized to fit your needs. It’s available with a 1.2, 1.7 or 2.2-meter belt sludge dewatering equipment. Say goodbye to one-size-fits-all at Charter. We tailor our designs to fit your project like a glove.

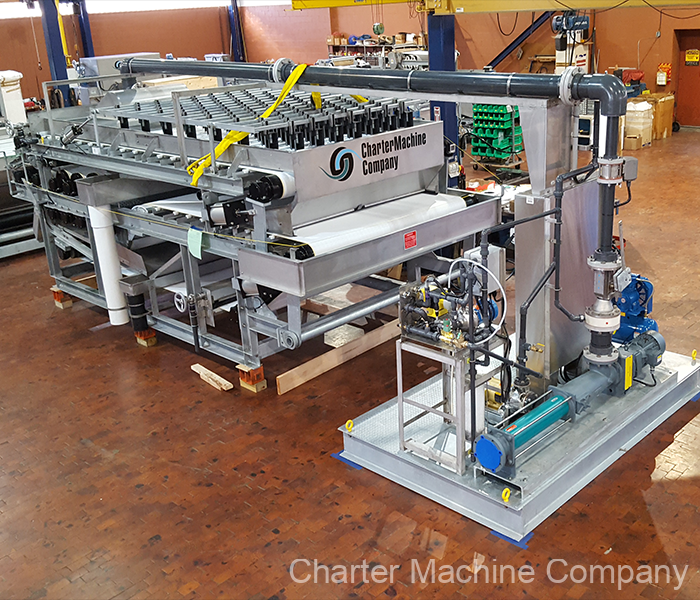

Mix and Match, Plug and Play

- CMC offers skid mounted systems that can be customized to meet any facility's needs. Our sump/skid systems can include the belt filter press only or be a complete "plug and play" system combining any combination of sludge feed pump, compressor, booster pump, in-line mixer, polymer system, conveyors, and control panel. See our Skid-Mounted Systems page to discover the perfect combination of size and flexibility.

Video

Machine Drawings

Product Brochure

Related Products

Related Services

Image Gallery