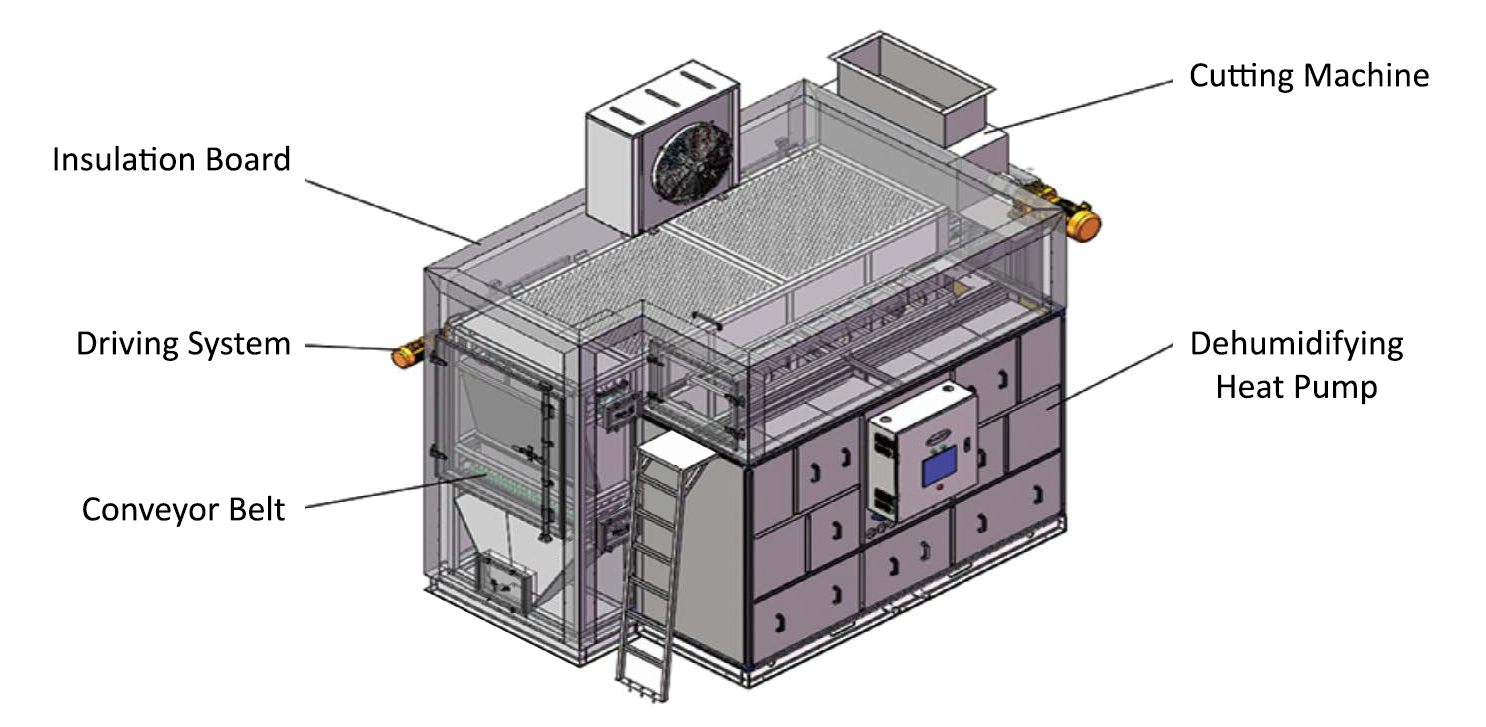

Evaporative Belt Dryer

Low Temperature

Revolutionize your drying process with the Low Temp Belt Dryer, a champion of efficiency and sustainability. It accepts input cake with a 10% to 45% dry solid content and effortlessly boosts it to an impressive 90%, significantly reducing waste volume.

Product Data

Description

The Low Temp Belt Dryer revolutionizes drying with its exceptional efficiency and environmental friendliness. It can handle input cake with 10% to 45% dry solids, achieving a remarkable reduction of up to 90% dry solids, surpassing industry standards. This translates to significantly less volume to manage and transport.

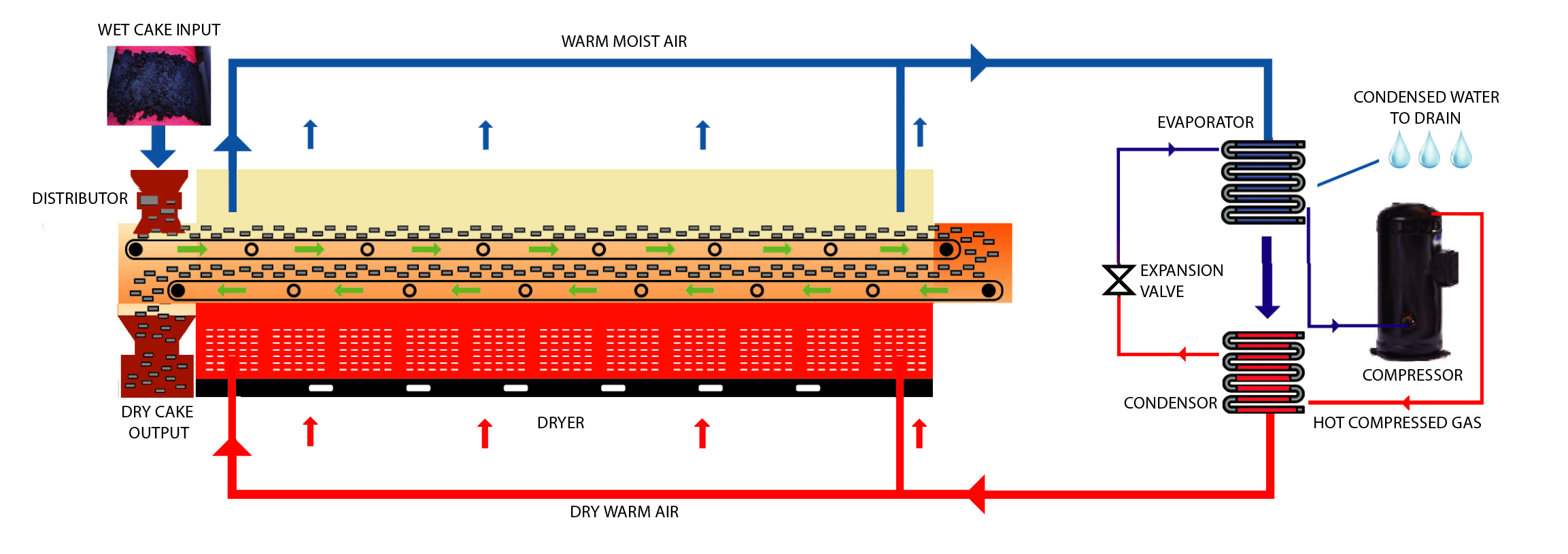

Furthermore, the innovative dehumidification system boasts a 1:4 ratio, double the industry average, ensuring superior moisture removal and eliminating the need for cumbersome deodorization equipment. Thanks to its closed-loop design, no heat is lost, resulting in 100% utilization and minimal energy consumption. Operating costs plummet to an impressive 300 kWh per ton of moisture removed, making it a highly cost-effective solution.

Safety is paramount, and the low operating temperature minimizes risks and provides a safer work environment. As an added bonus, the drying process effectively sterilizes the material, ensuring hygiene and compliance with regulations.

In essence, the Low Temp Belt Dryer offers a compelling combination of high efficiency, environmental consciousness, and cost savings, making it the ideal choice for a wide range of drying applications.

General Specifications

| Refrigerant | R134a |

|---|---|

| Power Supply | 480V / 3P / 60hz |

| Drying Temperature | 48~50C(return air/65~80C(air supply) |

| Control System | Touch Screen + PLC |

| Range of Wet Sludge at Inlet | Mositure Content (40%~83%) [variable based on sludge type] |

| Range of Dry Sludge at Outlet | Mositure Content (10%~60%) [variable based on sludge type] |

| Shaping Method | Strip Cutting, Strip Extruding |

Models

| MODEL | 1200 | 2400 | 7200 |

|---|---|---|---|

| Water Removal Rate/24hr | 1200kg | 2400kg | 7200kg |

| Water Removal Rate/hr | 50kg | 100kg | 300kg |

| Power Use | 14kWh | 26kWh | 76kWh |

| Heat Pump Module Qty | 1 set | 1 set | 3 sets |

| Air Compressor Qty | 1 set | 4 sets | 12 sets |

| Cooling Method | Air Cooling | Air Cooling | Air Cooling |

| Outline Dimension (mm) | 3170x1580x2080 | 3810x2215x2420 | 9500x2215x2420 |

| Structure | Assembled | Assembled | Assembly required |

| Weight | 2.0t | 3.2t | 8.0t |

Features

Schematic

Benefits

- Input cake 10%~45% dry solid, reduction upto 90% dry solid

- 1:4 dehumidification ratio, double the industry standard

- No odor emission, no need to install deodorization device

- No heat loss, 100% heat utilization

- Operating cost as low as 300 kWh/ton removed

- Low temperature for safer operation

- Effective sterilization

Related Products

Related Services

Image Gallery