Emulsion - Polymer Systems

Get Thicker Quicker

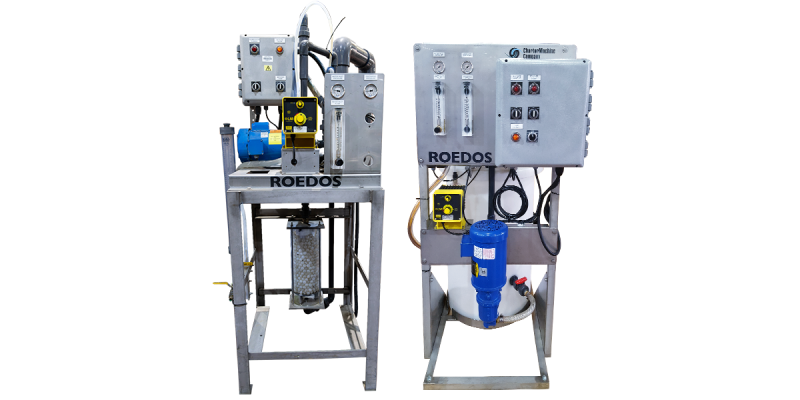

Our most popular units, the L-1 and the L-2 system, utilize emulsion polymers and can fit a wide range of applications.

Product Data

Description

It all starts with the right polymer.

Effective solid settling and thickening requires the right polymer selection. The polymer solution acts as the physical bridge that connects the suspended solids together, promoting liquid separation. The chief issue interfering with polymer efficiency occurs when molecular chains are bound tightly together reducing the particle’s contact area. A truly effective polymer solution should be selected and aged properly to achieve its highest activation, resulting in the unfolding of the molecular chains. Improper selection and/or mixing results in higher polymer consumption and lower system performance. Our in-house testing facility offers sample testing to assist in assuring optimal performance for our polymer systems.

Our most popular units, the L-1 and the L-2 system, utilize emulsion polymers and can fit a wide range of applications. Charter Machine can also design and customize polymer systems to meet customer requirements.

Our Roedos line of polymer systems provide the proper aging time while ensuring that the correct solution is always available to allow adjustments of your process requirements. Utilizing variable speed type pumps, the Roedos injects the polymer solution into the water or sludge stream. We do not rely on the incoming water pressure that can vary or be too low to properly prepare and transport the polymer solution into the water or sludge line.

Models

| Model | Mixing/Holding Capacity (Gallons) | Type of Polymer | Power Requirements | ||

|---|---|---|---|---|---|

| Liquid | Emulsion | Dry | |||

| Roedos L-1 | 50 | X | 120V/1PH/60Hz | ||

| Roedos L-2.10 | Variable | X | 120V/1PH/60Hz | ||

| Roedos L-2.20 | Variable | X | 120V/1PH/60Hz | ||

| Roedos 500 | 500/500 | X | X | X | 480V/3PH/60Hz |

| Roedos III | 300/450 | X | X | X | 480V/3PH/60Hz |

| Roedos VI | 600/750 | X | X | X | 480V/3PH/60Hz |

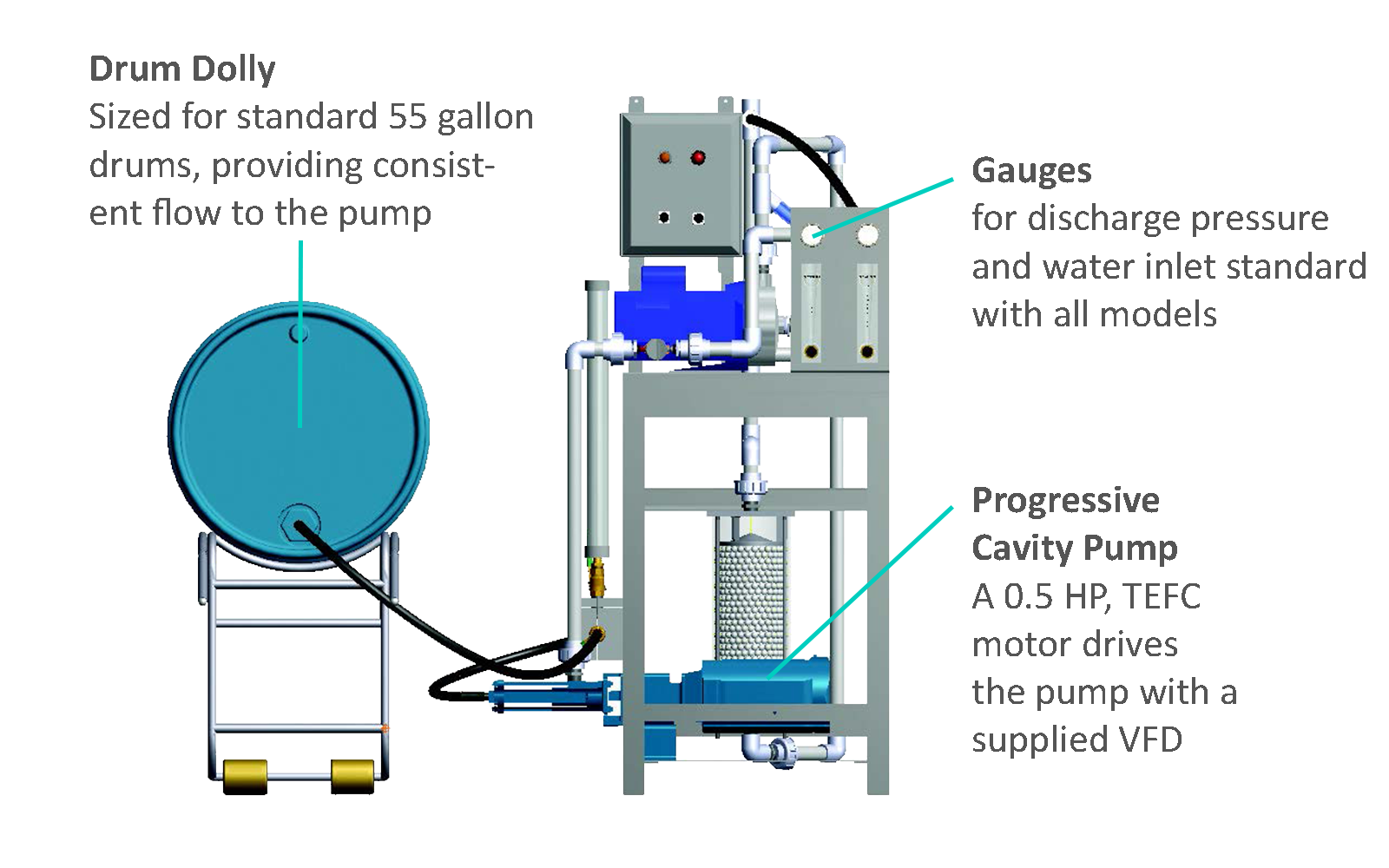

L-1

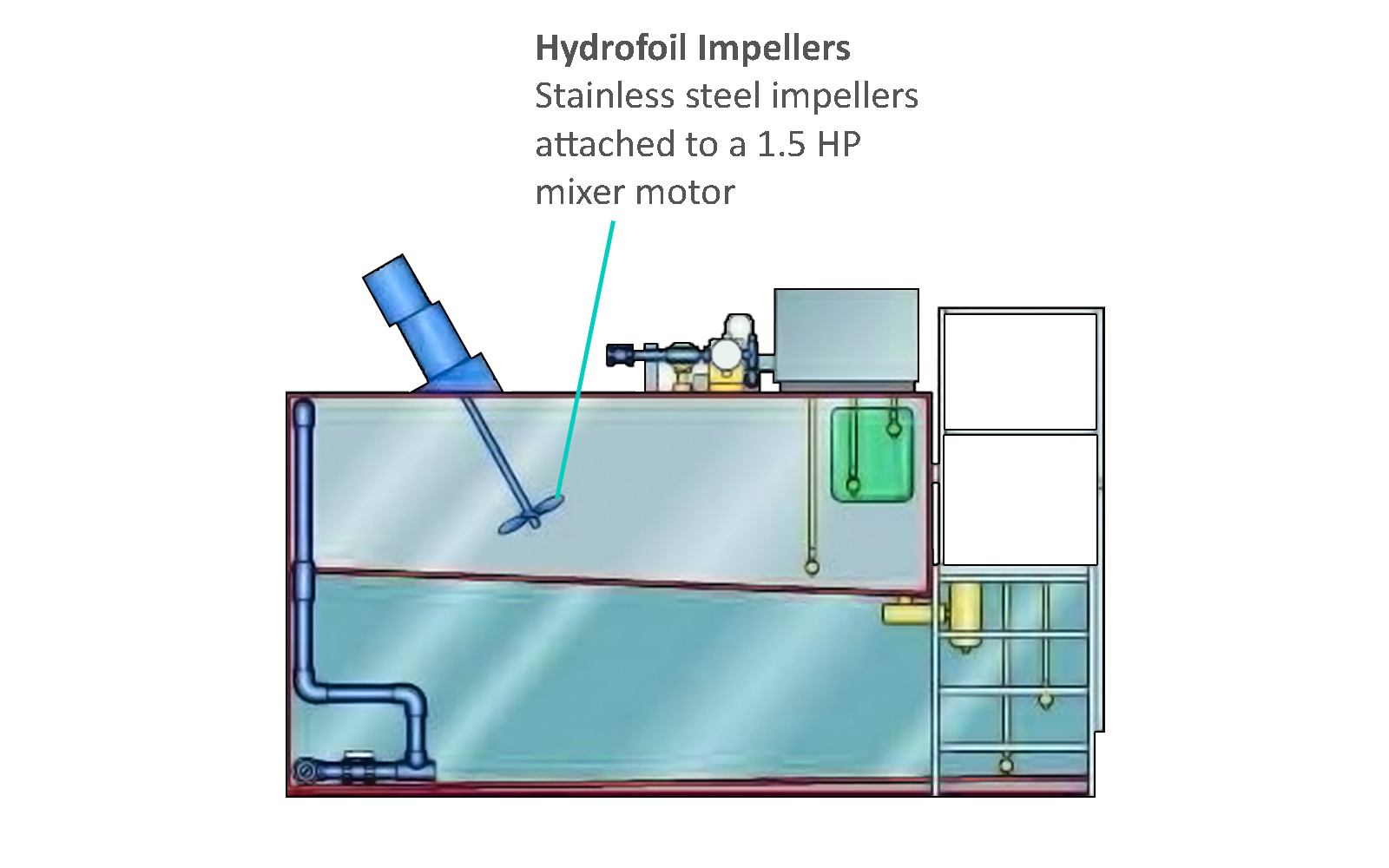

- Mix/aging tank - Built in 50 gallon high density Polyethylene mix/aging tank with mechanical mixer

- Level sensor - for automatic continuous operation

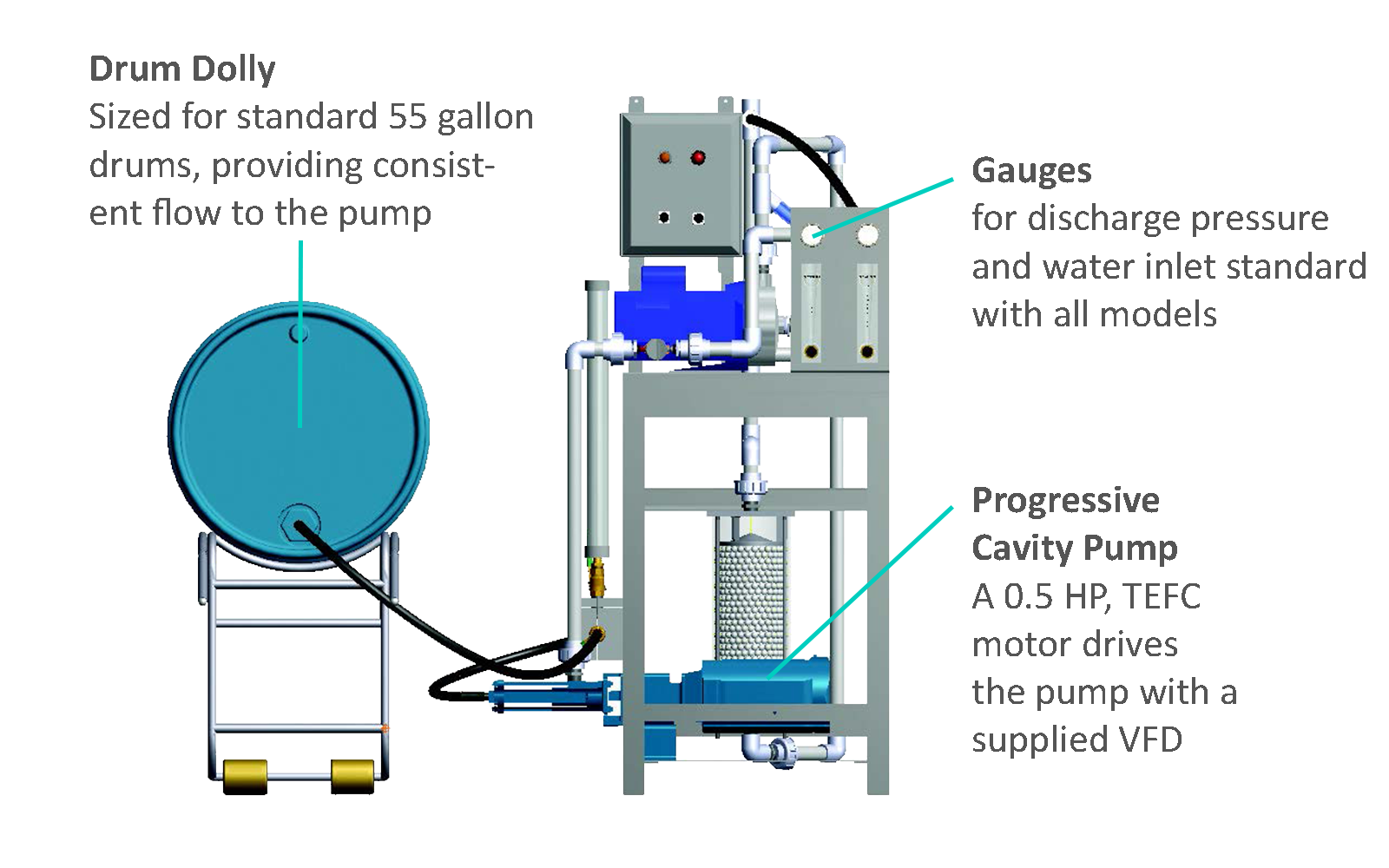

- Metering pump - from 8 GPH to 20 GPH of emulsion polymer

- Pump - Variable speed positive displacement type pump to feed aged/mixed polymer

- Control panel - supporting fully automatic and manual operation

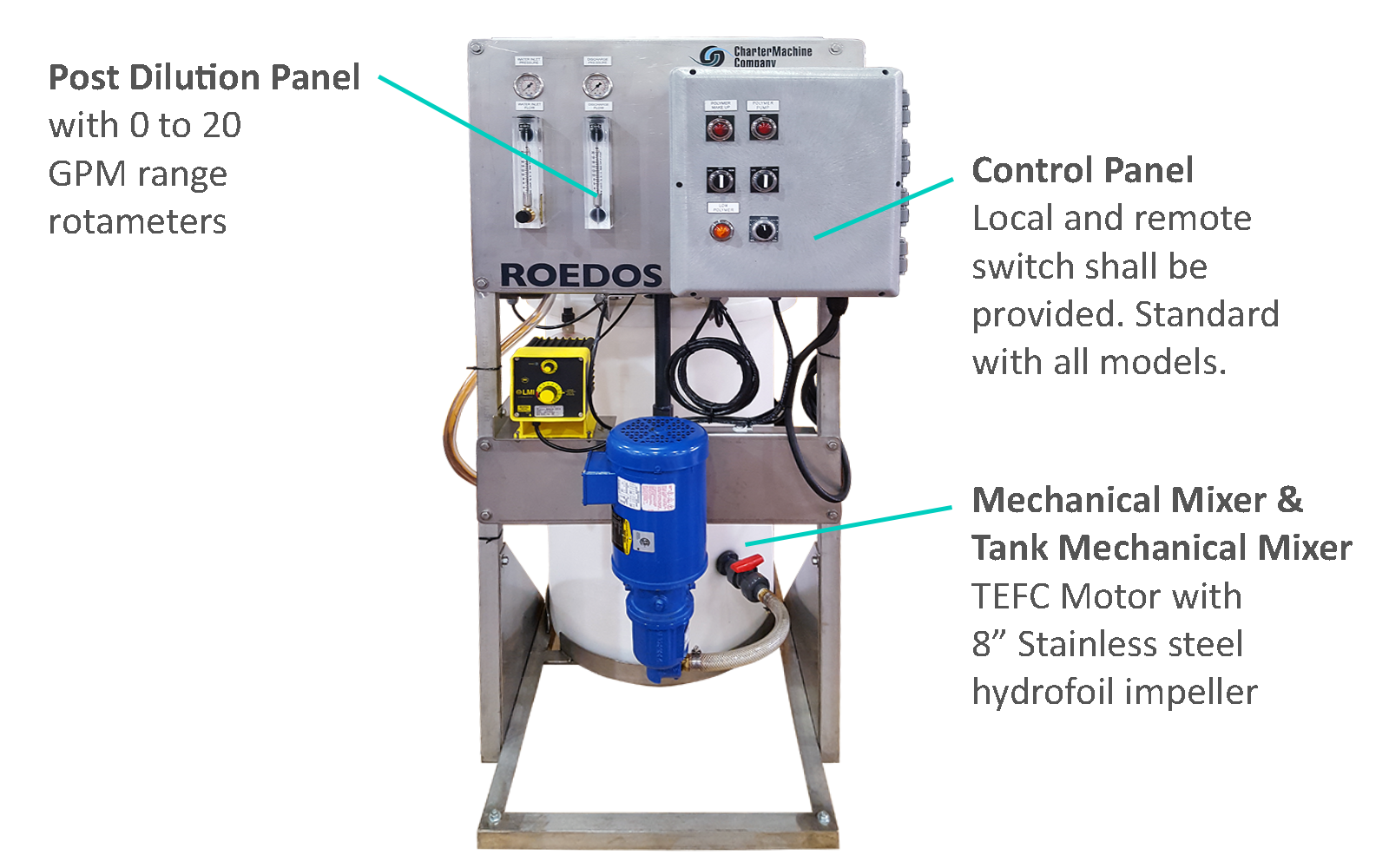

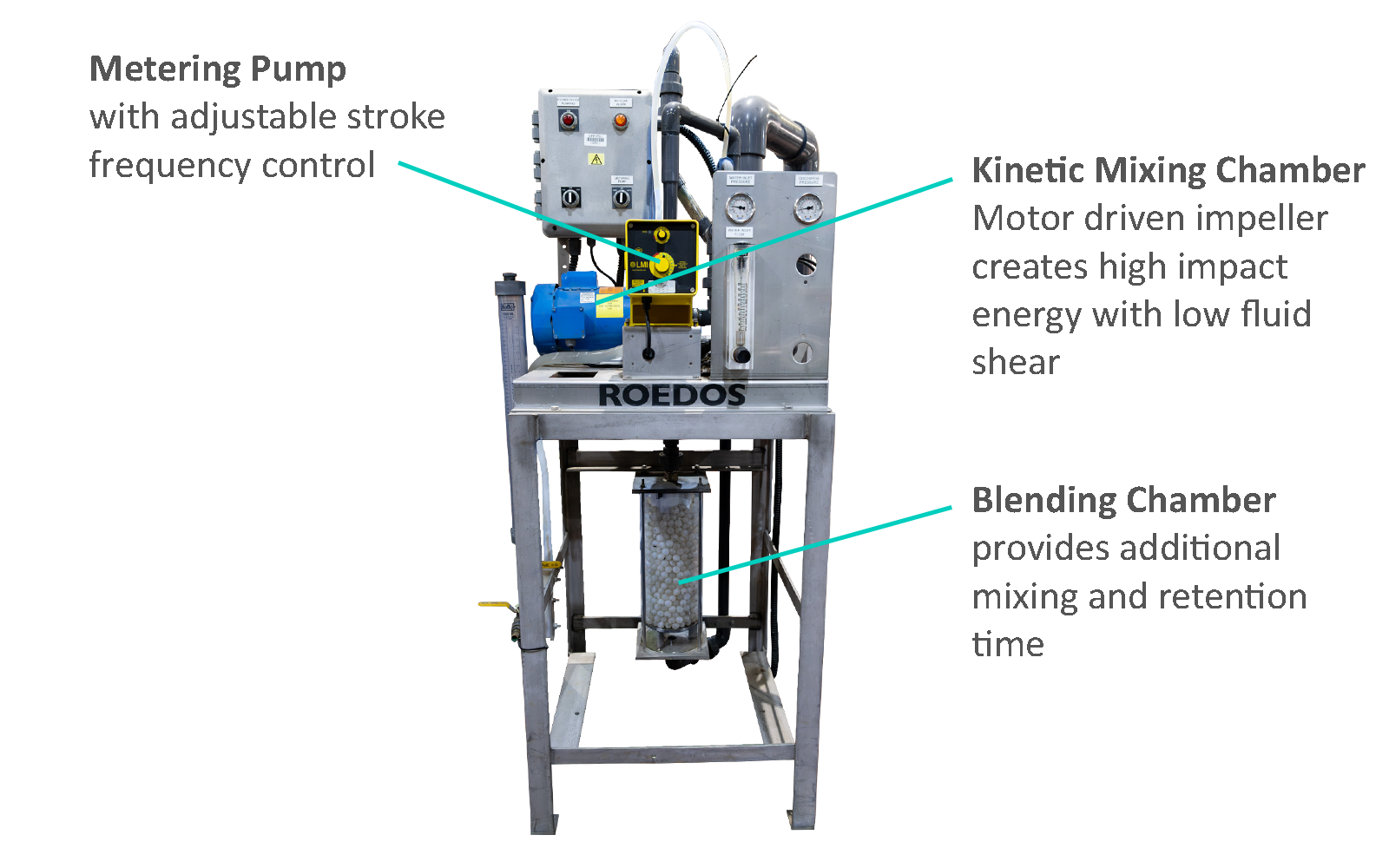

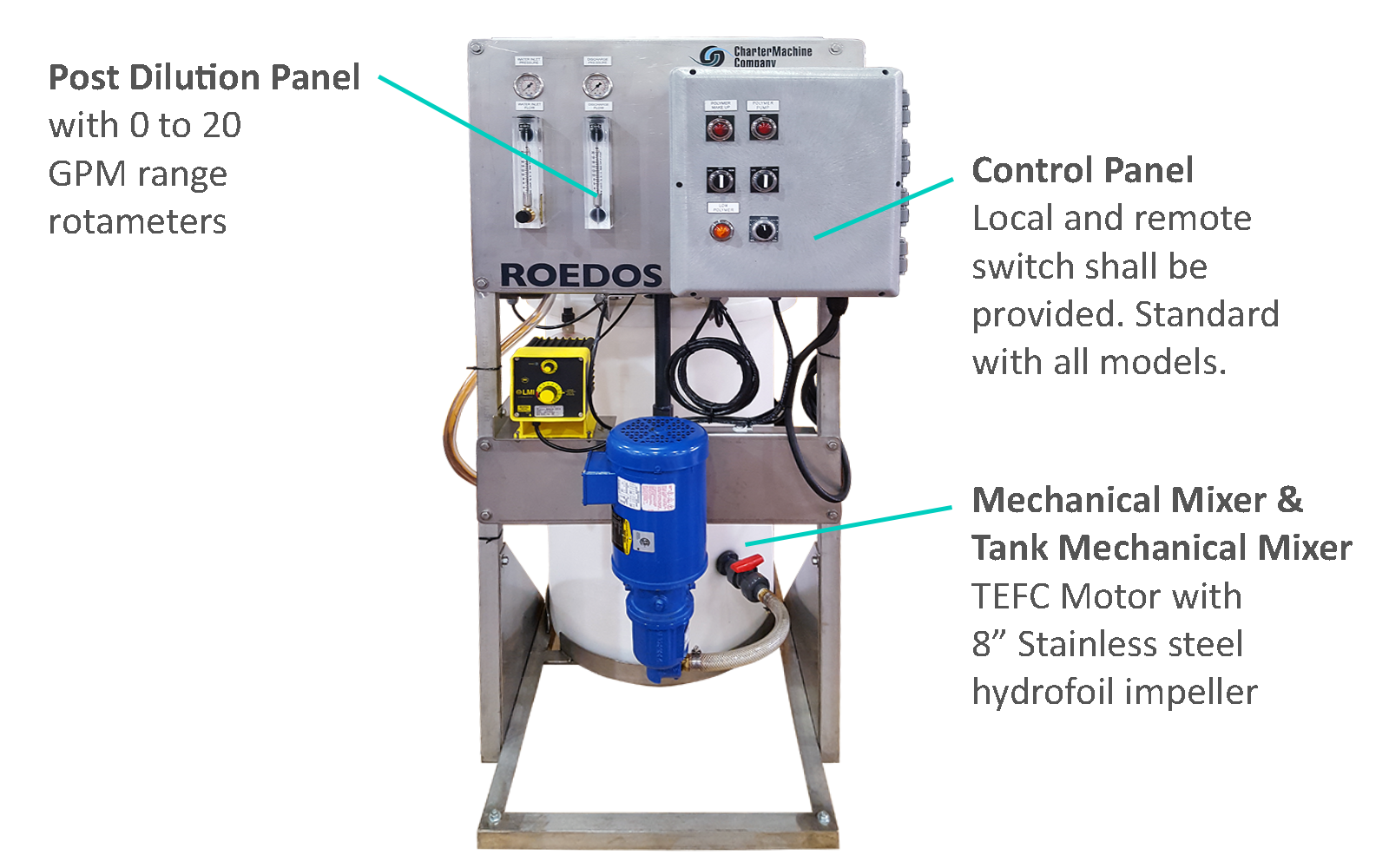

L-2.1

- Multi-zone Systematic Mixing

- Volumetric Mixing Chamber

- Blending Chamber - providing additional mixing and retention time

- Calibration Column Reading - in both gpm and ml

- Post Dilution Meter

- Control Panel - easily accessible, waist height control panel

- Small Footprint - 24” by 26” footprint

- Metering Pump - from 4 GPH to 20 GPH of emulsion polymer

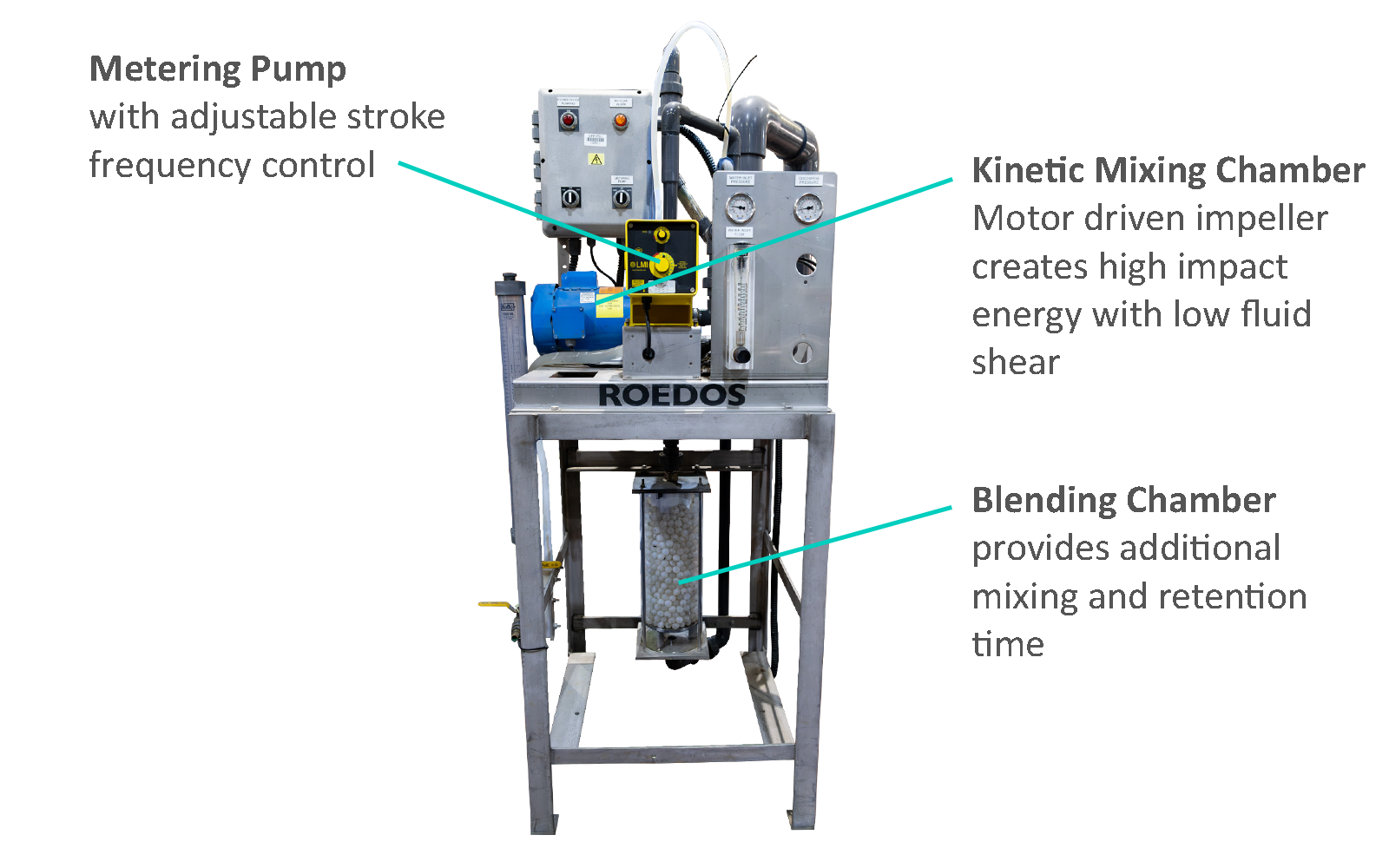

L-2.2

- Multi-Zone Systematic Mixing

- Volumetric Mixing Chamber

- Blending Chamber - providing additional mixing and retention time

- Calibration column reading – in both gpm and ml

- Post Dilution Meter

- Control Panel - Easily accessible, waist height control panel

- Low Flow Alarm

500

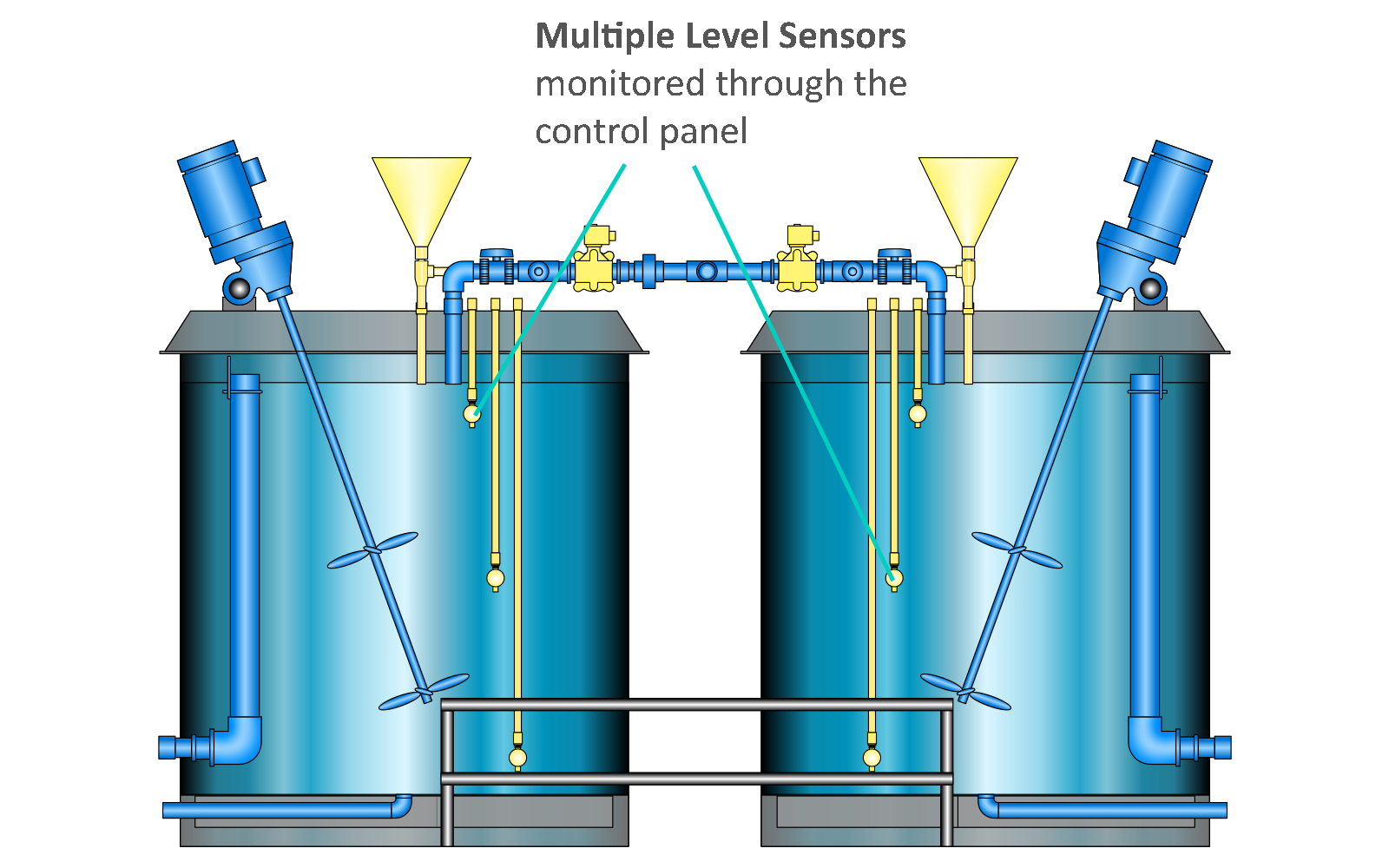

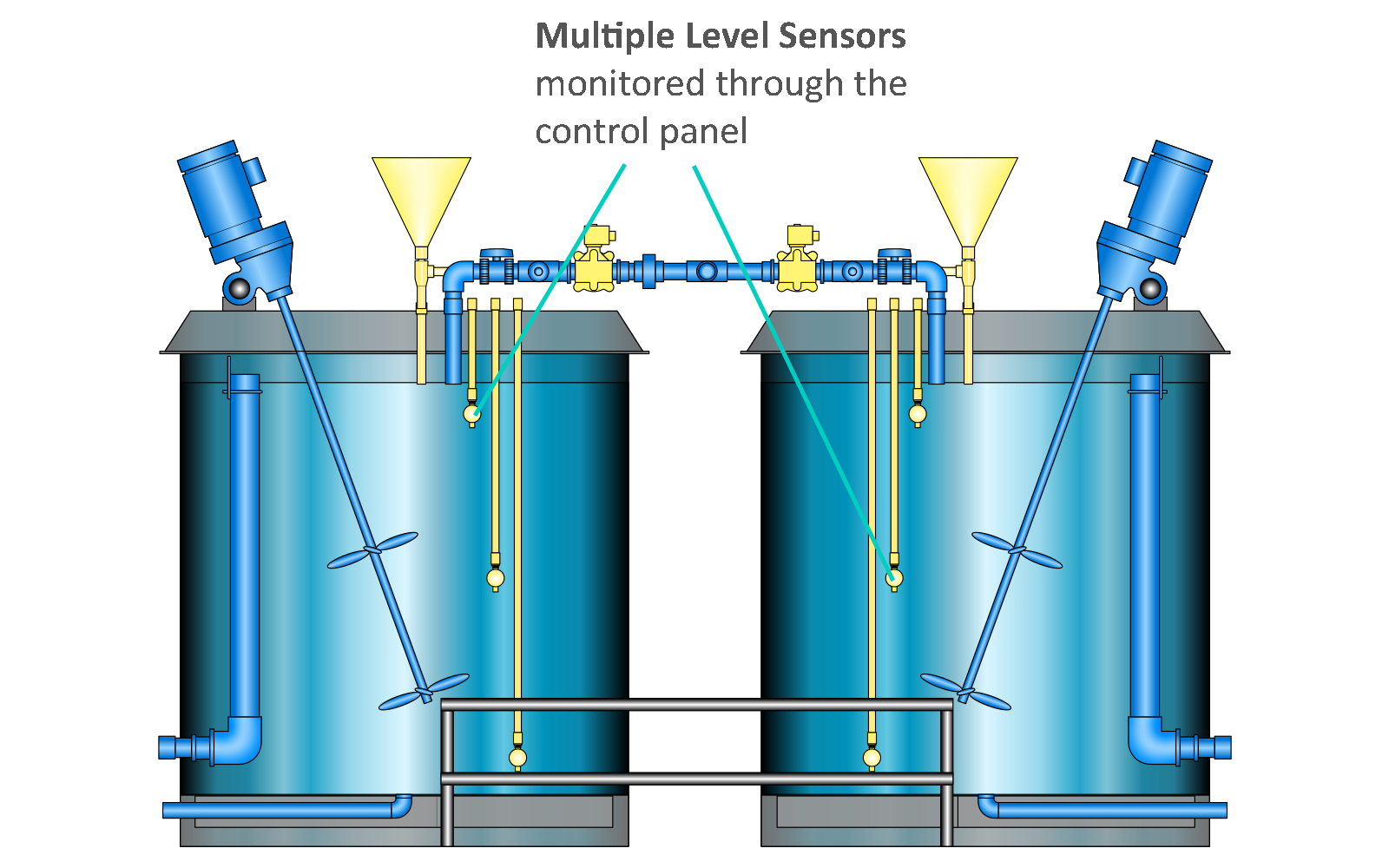

- Dual Tanks - Highly efficient and versatile with two 500-gallon capacity tanks. Separate tanks for preparing/aging and storing/dosing of stock solution.

- Pumps - Variable speed positive displacement pumps supply diluted/mixed polymer to dewatering unit (not shown)

- Multiple Level Sensors - monitored through the control panel

- Control Panel - supporting fully automatic and manual operation

- Versatile Application - For liquid (mannich), emulsion or dry polymers

- Thorough dispersion of polymers, assuring effective polymer wetting reducing hydration and blending time. This also eliminates “fish-eyes” or clumping of polymer.

III / VI

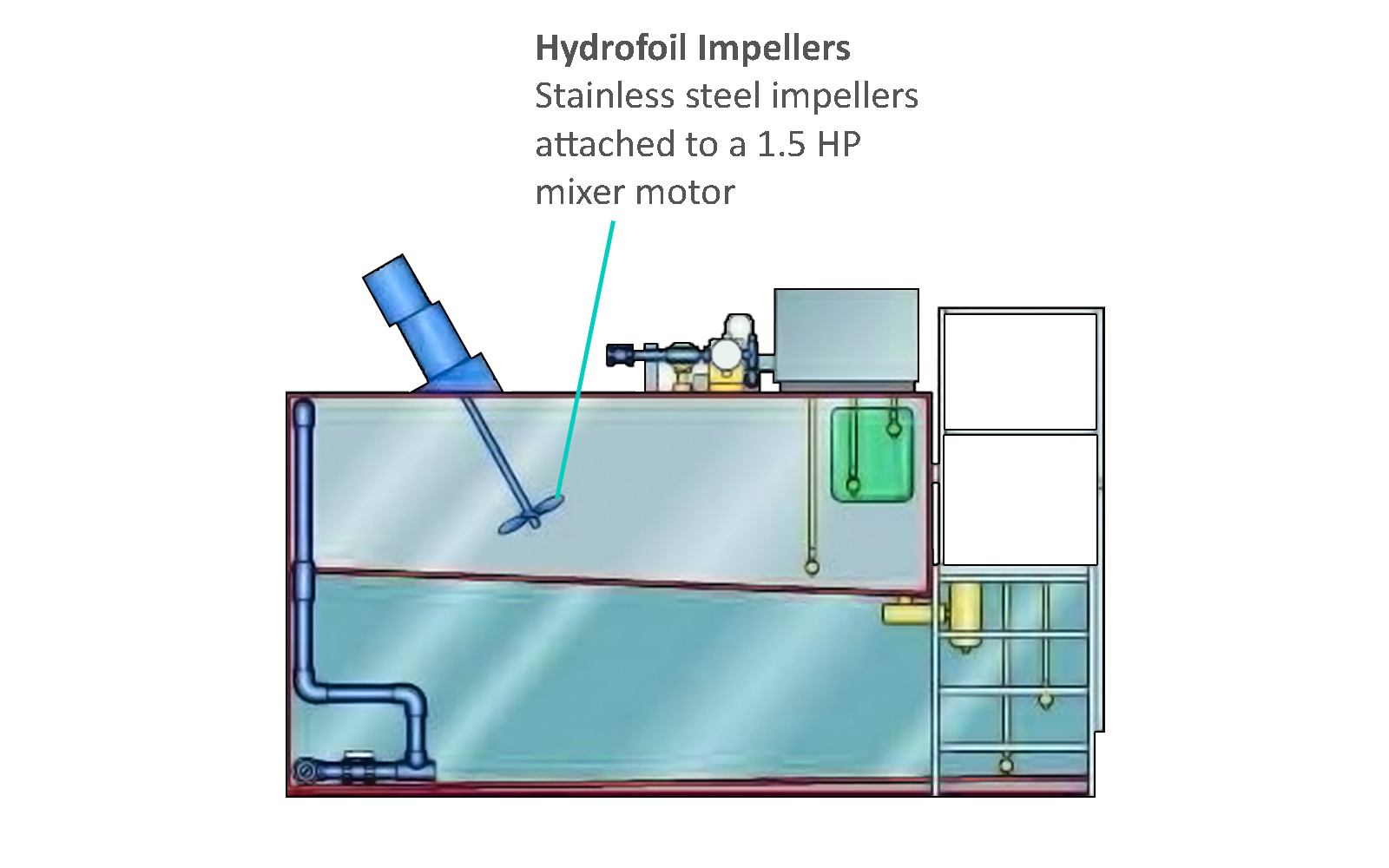

- Volumetric Screw Feeder - with dry systems to accurately transport the polymer in mixing tank

- 300, 600 and 1,100 gallon capacity models

- High capacity/small footprint

- Stacked mix and feed tanks maximizes floor space

- Primarily utilized with dry polymers but can condition any type polymer

- Thorough dispersion of polymers, assuring effective polymer wetting reducing hydration and blending time. This also eliminates “fish-eyes” or clumping of polymer.

- Control Panel - Manual, semi-automatic or fully automatic continuous operation

- Polymer feed range up to 30 lbs/hr* for dry polymer and 20 GPM for emulsion and liquid

- Pump - One variable speed positive displacement pump to feed mixed polymer

- OSHA Compliant - stairs, railings, and platforms

- Level sensors - monitored through the control panel

* for 0.6% polymer solution in batch operation

Features

Inline Venturi Type Mixer

- Polymer solution and sludge are rapidly mixed in our inline venturi type mixer. *Mixing energy is easily adjustable.

Multi-Port Injection Ring

- The polymer solution is pumped into the line through our multi-port injection non-clog polyethylene ring ensuring the best initial introduction possible.

Non-Corrosive Construction

- All units built with non-corrosive construction stainless steel components and Schedule 80 PVC piping.

L-1

- Mix/aging tank - Built in 50 gallon high density Polyethylene mix/aging tank with mechanical mixer

- Level sensor - for automatic continuous operation

- Metering pump - from 8 GPH to 20 GPH of emulsion polymer

- Pump - Variable speed positive displacement type pump to feed aged/mixed polymer

- Control panel - supporting fully automatic and manual operation

L-2.1

- Multi-zone Systematic Mixing

- Volumetric Mixing Chamber

- Blending Chamber - providing additional mixing and retention time

- Calibration Column Reading - in both gpm and ml

- Post Dilution Meter

- Control Panel - easily accessible, waist height control panel

- Small Footprint - 24” by 26” footprint

- Metering Pump - from 4 GPH to 20 GPH of emulsion polymer

L-2.2

- Multi-Zone Systematic Mixing

- Volumetric Mixing Chamber

- Blending Chamber - providing additional mixing and retention time

- Calibration column reading – in both gpm and ml

- Post Dilution Meter

- Control Panel - Easily accessible, waist height control panel

- Low Flow Alarm

500

- Dual Tanks - Highly efficient and versatile with two 500-gallon capacity tanks. Separate tanks for preparing/aging and storing/dosing of stock solution.

- Pumps - Variable speed positive displacement pumps supply diluted/mixed polymer to dewatering unit (not shown)

- Multiple Level Sensors - monitored through the control panel

- Control Panel - supporting fully automatic and manual operation

- Versatile Application - For liquid (mannich), emulsion or dry polymers

- Thorough dispersion of polymers, assuring effective polymer wetting reducing hydration and blending time. This also eliminates “fish-eyes” or clumping of polymer.

III / VI

- Volumetric Screw Feeder - with dry systems to accurately transport the polymer in mixing tank

- 300, 600 and 1,100 gallon capacity models

- High capacity/small footprint

- Stacked mix and feed tanks maximizes floor space

- Primarily utilized with dry polymers but can condition any type polymer

- Thorough dispersion of polymers, assuring effective polymer wetting reducing hydration and blending time. This also eliminates “fish-eyes” or clumping of polymer.

- Control Panel - Manual, semi-automatic or fully automatic continuous operation

- Polymer feed range up to 30 lbs/hr* for dry polymer and 20 GPM for emulsion and liquid

- Pump - One variable speed positive displacement pump to feed mixed polymer

- OSHA Compliant - stairs, railings, and platforms

- Level sensors - monitored through the control panel

* for 0.6% polymer solution in batch operation

Benefits

Non-Corrosive Construction

• All units built with non-corrosive construction stainless steel components and Schedule 80 PVC piping.

Independent System

• Our Roedos systems maintain a constant dosing rate independent of pressure variations in either the water or sludge line.

Design Flexibility

• Charter Machine offers products for both emulsion and dry polymer systems. CMC can also design and customize polymer systems to meet customer requirements.

Applications

MUNICIPAL

| WASTEWATER / DRINKING WATER | |

|

|

|

|

INDUSTRIAL

|

|

|

|

AGRICULTURE

|

|

|

|

FOOD & BEVERAGE

|

|

|

|

OTHER

|

|

Machine Drawings

Product Brochure

Related Products

Related Services

Image Gallery