Royal Screw Press

Highest Efficiency, Unsurpassed Quality

The Royal Screw Press achieves very high efficiency with a low power consumption due to the low-speed operation. The power range is from 0.75 kW to a maximum of 5.5 kW with flow rates up to 200 GPM while producing 25%+T.S.cake.

Product Data

Description

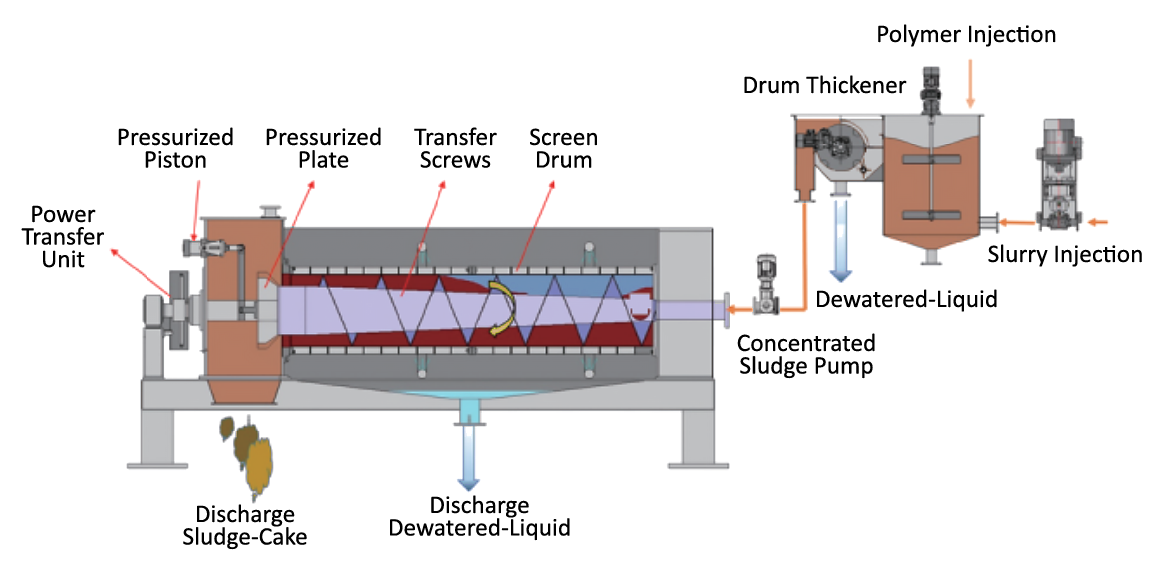

The Charter Royal Screw Press is a high-efficiency rotary screw press with low power operation, allowing you to save on energy costs. Our Royal Screw Press is based upon a technology that produces sludge that is cohered to the mechanical extractor, the filtrate then ejects from the inlet part by the energy of the screw rotated at a low speed, (0.2~1.3rpm). This is comprised of the screen classified into the strong screw wing of the structure and concentration part, dehydration part, and compressor.

Models

| MODEL | CAPACITY | POWER (kW) | WEIGHT (Ton) | LENGTH | WIDTH | HEIGHT |

|---|---|---|---|---|---|---|

| KOWATS-300 SP | 8m3/h (35GPM) | 0.75 | 1.5 | 9'-2" | 2'-6⅜" | 3'-8" |

| KOWATS-500 SP | 13m3/h (55GPM) | 1.5 | 4.1 | 13'-7½" | 3'-7⅜" | 4'-6¾" |

| KOWATS-700 SP | 18m3/h (80GPM) | 2.2 | 7.6 | 18'-6¾" | 8'-4½" | 5'-11⅝" |

| KOWATS-900 SP | 25m3/h (110GPM) | 3.3 | 11 | 23'-11½" | 9'-2¼" | 7'-4¼" |

| KOWATS-1000 SP | 30m3/h (130GPM) | 3.7 | 12.3 | 26'-1½" | 11'-1⅞" | 7'-9¾ " |

| KOWATS-1200 SP | 40m3/h (175GPM) | 5.5 | 17.6 | 28'6-½" | 12'-5⅝" | 8'-5⅝" |

Throughput and dry solid would vary depending on the sludge characteristics and the specifications are subject to change without prior notice.

Features

Screw Blade Screw Blade |

Main Drum Main Drum |

Chamber & Shuttle Washing Device Chamber & Shuttle Washing Device |

Main Screw Fabrication Main Screw Fabrication |

Self Cleaning Nozzle Self Cleaning Nozzle |

Drum Thickener Device Drum Thickener Device |

Schematic

Benefits

High Energy Efficiency

- Max. 45m3/hr (200GPM) with 5.5kW with discharging 25%DS.

- The Royal Screw Press achieves very high efficiency with a low power consumption due to the low-speed operation. The power range is from 0.75 kW to a maximum of 5.5 kW with flow rates up to 200 GPM while producing 25%+T.S.cake.

Large Capacity Processing

- Optional Thickener can increase the capacity & Sludge dryness.

- The optional combination of the pre-thickening drum with the slow steady pressing operation which is controlled via a pneumatic backpressure plate allows for the most dewatering flexibility of any screw press in the industry.

- The Royal designed screw press has the option to have a drum thickener to concentrate low concentration incoming feed solids up to 3-5%T.S. which increases the throughput capacity of the press. This allows for a higher solids loading rate to the screw while maintaining a high volumetric rate to the system.

Auto-cleaning system

- Nozzles in a circumferential direction clean the entire drum automatically.

- The self-cleaning nozzle design prevents nozzle clogging and lengthens time between maintenance.

Low O&M Cost

- Durable machine & robust materials make low cost for long period.

- The robust design utilizing thick stainless-steel supports, screw, screen, and frame lead to very low maintenance costs.

- Washing water reduction by over-95% recovery rate of ss.

Ultra-low noise

- Only 30dB noise level by low-speed operation

- The low-speed operation combined with the low power motor, equates to the quietest screw press in the industry with only 30 dB noise level.

Distraction-free

- Airtight deodorant cover allows for an odor-free stable working environment.

Applications

MUNICIPAL

| WASTEWATER / DRINKING WATER | |

|

|

|

|

INDUSTRIAL

|

|

|

|

AGRICULTURE

|

|

|

|

FOOD & BEVERAGE

|

|

|

|

OTHER

|

|

Video

Product Brochure

Related Products

Related Services

Image Gallery