BP 8000

Two in One Sludge Processing

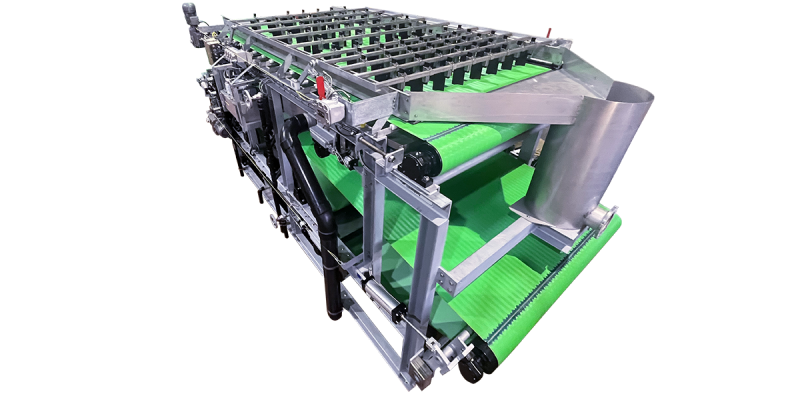

For plants with limited space of dealing with sludge volume that exceeds the capabilities of traditional belt filter press, Charter Machine Company suggests our 3-Belt Press. It is a gravity belt thickener and belt filter press combined into a single unit.

Product Data

Description

Sizes and speeds to meet your needs.

Available with 1.2, 1.7, or 2.2- meter width belts, the 3-Belt Press features an independent gravity deck with its own variable speed belt-drive to accommodate higher feed rates on the gravity deck. The Belt Filter Press wedge zone and pressure sections are allowed to maintain a slower belt speed, thus maximizing the units de-watering capability for the driest cake possible.

Small package, big results.

A 3-Belt Press eliminates the need for a separate gravity belt thickener but can still be outfitted with the option of running the unit as a thickener only. By allowing this option along with the belt filter press feature, it provides great versatility to the facility while reducing the demand for floor space.

Designed to perform.

The BP8000 3-Belt unit is excellent for handling thin sludges in one operation but can be very efficient with various sludge types. In addition to wastewater treatment and water plant facilities, the 3- Belt unit is extremely cost effective for many industrial accounts due to its versatality.

Models

| MODEL | # ROLLS | DECK STYLE | OAL | PLI | BELT WIDTH |

|---|---|---|---|---|---|

| BP12.83 | 8 | LONG | 22’-7 ½” | 50 | 1.2 M |

| BP12.183 | 8 | LONG | 21'-1 ⅝" | 50 | 1.2 M |

| BP12.182 | 8 | SHORT | 50 | 1.2 M | |

| BP17.83 | 8 | LONG | 22’-7 ½” | 50 | 1.7 M |

| BP17.183 | 8 | LONG | 21'-1 ⅝" | 50 | 1.7 M |

| BP17.182 | 8 | SHORT | 50 | 1.7 M | |

| BP22.83 | 8 | LONG | 22’-7 ½” | 50 | 2.2 M |

| BP22.183 | 8 | LONG | 21'-1 ⅝" | 50 | 2.2 M |

| BP22.182 | 8 | SHORT | 50 | 2.2 M |

Features

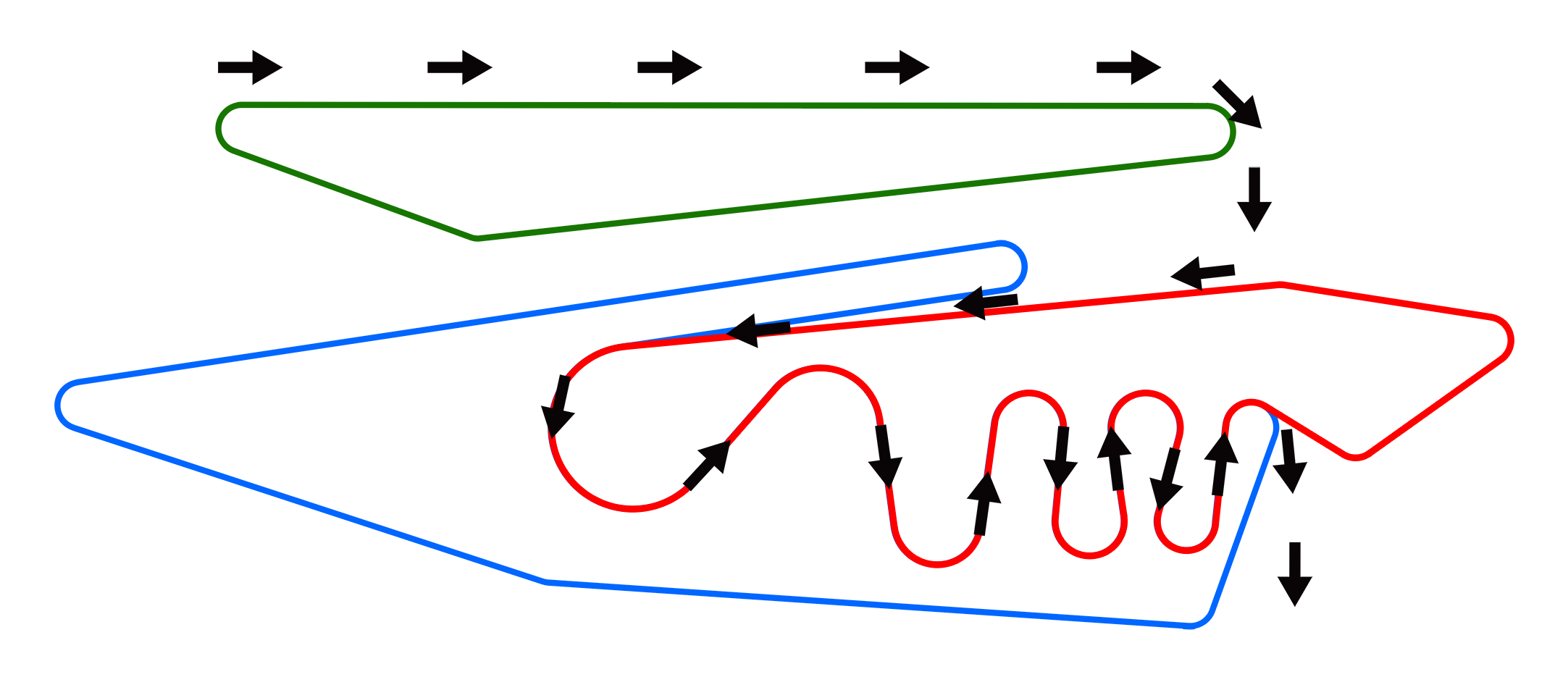

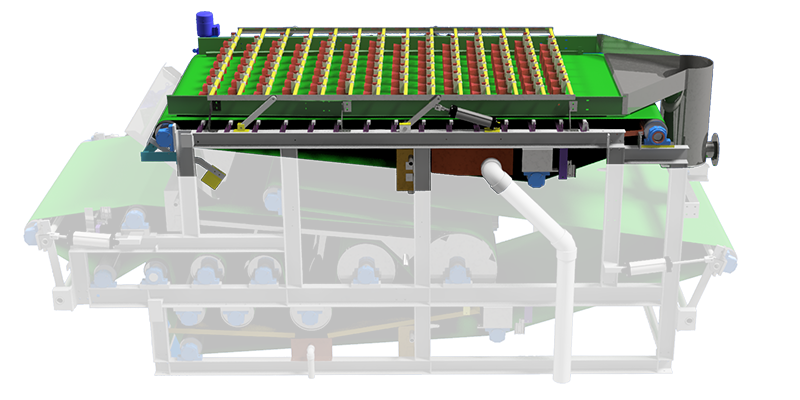

3-Belt Technology

The 3-Belt Press features an independent gravity deck with its own variable speed belt-drive to accommodate higher feed rates on the gravity deck. The Belt Filter Press wedge zone and pressure sections are allowed to maintain a slower belt speed, thus maximizing the units de-watering capability for the driest cake possible.

Independent Gravity Zone

Provides for separate gravity dewatering function independent of the belt press operation. The independent gravity deck can be outfitted with the option of running the unit as a thickener only. By allowing this option along with the belt filter press feature, it provides great versatility to the facility while reducing the demand for floor space.

Center Pivot Tracking

Charter Machine utilizes a Pneumatic / Hydraulic controlled center pivot alignment system. This design reduces belt stretching, lengthens belt life and provides a more consistent performance over the life of the belt.

Belt Tensioning

Pneumatic / Hydraulically controlled rigid tensioning assembly adjusts and maintains belt tension with parallel movement for extended belt life.

One Piece Bearings

Charter Machine utilizes Rilsan Nylon coated one-piece solid pillow block bearing housings with gasketed end plate. Self-aligning double-row spherical bearings with quadruple lip seals. The contact surface of the shafts shall have a 60-micrometer polished finish to increase seal life and each stub shaft shall be held in place with a lock ring to guarantee alignment.

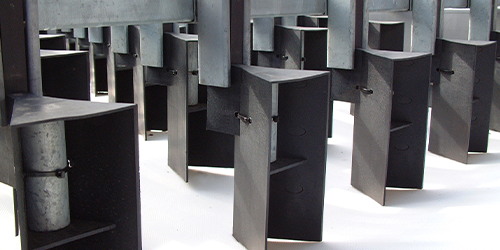

Plow Grid

|

Pneumatic / Hydraulic actuator lifts or lowers entire plow assembly for easier cleaning, eliminating systems manually lifting each row of plows. Plows “float” on belt and can be replaced without the use of tools.

Benefits

Reduced Costs

- Low polymer and power consumption

Maximum Performance

- Superior solids capture ratio

- Charter's three belt technology allows independent speed control regarding the gravity deck area versus the sheer/pressure zone. Thus, maximizing the units de-watering capability for the driest cake possible.

Small Footprint

- A 3-Belt Press eliminates the need for a separate gravity belt thickener but can still be outfitted with the option of running the unit as a thickener only. By allowing this option along with the belt filter press feature, it provides great versatility to the facility while reducing the demand for floor space.

- BP8000 units are available in short deck versions where space is a premium.

Low Maintenance, Streamlined Operation

- Pneumatically actuated sludge plow assembly

- Interchangeable spherical roller bearings

Sustainable, Non-Corrosive Construction

- Increased lifespan: Charter strives to meet the needs of their clients whether it is the typical hot-dipped galvanized frame with stainless steel components or complete stainless-steel, 304, 316 S.S, models. These non-corrosive materials last longer, reducing maintenance costs and replacement needs.

- Improved safety: Corrosion can weaken structures and compromise safety. Using our non-corrosive equipment minimizes this risk of those operating in any around the vicinity.

- Enhanced aesthetics: Many non-corrosive materials have a clean and modern appearance, contributing to the overall aesthetics of a project.

- Environmental benefits: Corrosion can lead to the release of harmful chemicals into the environment. Using non-corrosive materials reduces this risk and promotes sustainability.

Multiple Sizes

- BP8000 is sized to fit your needs. It’s available with a 1.2, 1.7 or 2.2-meter belt sludge dewatering equipment. Say goodbye to one-size-fits-all at Charter. We tailor our designs to fit your project like a glove.

Mix and Match, Plug and Play

- CMC offers skid mounted systems that can be customized to meet any facility's needs. Our sump/skid systems can include the belt filter press only or be a complete "plug and play" system combining any combination of sludge feed pump, compressor, booster pump, in-line mixer, polymer system, conveyors, and control panel. See our Skid-Mounted Systems page to discover the perfect combination of size and flexibility.

Video

Machine Drawings

Related Products

Related Services

Image Gallery