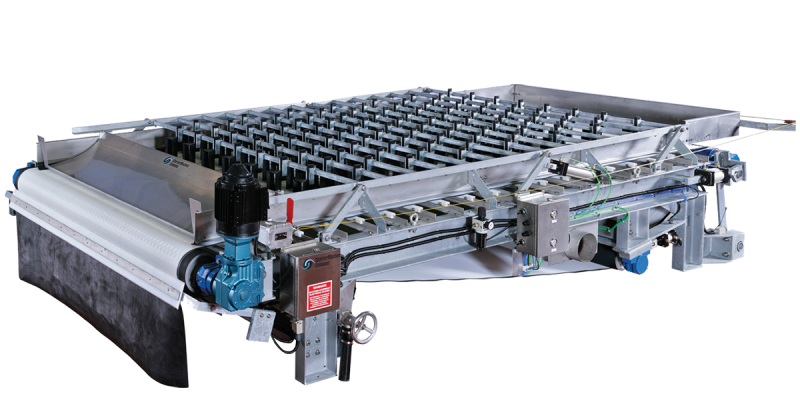

Gravity Belt Thickener

Intelligent design. Robust construction.

The Gravity Belt Thickener is a highly effective tool for dewatering. It operates quietly at a minimal cost, consuming a low volume of wash water. Sludge is flocculated by the use of polymers, introduced on the belt and the released water is drained through the gravity belt. The GBT is hands down the most cost effective way to thicken solids.

Product Data

Description

Our ROEBELT Gravity Belt Thickeners (GBT) reduce the volume of thin sludges and slurries produced during municipal or industrial wastewater treatment. The principle of the GBT is simple: Sludge is flocculated with polymers, released water is drained by gravity through a traveling filter belt.

Charter's Gravity Belt Thickener offers more than results. It delivers ease and dependability. The center-pivot steering system reduces belt stretching, providing longer and more consistent performance. The machine also incorporates 11 rows of plows for increased throughput and thickening. There is even a pneumatic plow lift, for easy operation and cleanup. The solid pillow block, quadruple sealed bearing cases that reduce maintenance cost and down time are guaranteed for life. It is all there, built into a ridged non-corroding frame.

CMC's enclosed unit positions the stainless-steel hood near the gravity deck to control odor while still allowing visual inspection. This design also promotes easier cleaning and maintenance.

General Specifications

| SLUDGE TYPE | FEED % | CAKE % | FILTRATE CAPTURE % | POLYMER CONSUMPTION LBS/TON | RB812.3 LBS/DS/H GPM | RB817.3 LBS/DS/H GPM | RB822.3 LBS/DS/H GPM | RB832.3 LBS/DS/H GPM |

|---|---|---|---|---|---|---|---|---|

| PRIMARY | 2.5-7.5 | 7.5-12.5 | 98-99 | 2-8 | 2,000 80 |

3,500 140 |

5,000 200 |

7,500 300 |

| ANAEROBIC DIGESTED | 2-5 | 4.5-10.5 | 98-99 | 6-10 | 1,750 100 |

2,800 160 |

4,200 240 |

6,630 360 |

| 50% PRIMARY 50% SECONDARY |

1.5-5 | 4.5-8.0 | 98-99 | 6-10 | 1,790 110 |

2,930 180 |

4,390 270 |

7,320 450 |

| WASTE ACTIVATED | .5-1.5 | 4.5-7.0 | 98-99 | 8-12 | 1,110 220 |

1,600 320 |

2,500 500 |

3,900 780 |

| AEROBICALY DIGESTED | 1.5-3 | 4.5-7.5 | 98-99 | 10-14 | 1690 150 |

2,480 220 |

3,940 350 |

6,190 550 |

Models

| MODEL | OAL | BELT WIDTH |

|---|---|---|

| RB812.3 | 19'-6¾" | 1.2 M |

| RB817.3 | 19'-6¾" | 1.7 M |

| RB822.3 | 19'-6¾" | 2.2 M |

| RB832.3 | 19'-11¼" | 3.2 M |

Features

SS Pressure Plate

- Optional stainless steel pressure plate provides additional dewatering without breaking the floc or creating pooling of the filtrate.

Up-flow Feed Box

- Integral flocculation tank levels flow onto belt and provide ease of observation.

Center Pivot Alignment System

- CMC utilizes a pneumatically controlled center pivot alignment system. This design reduces belt stretching, lengthens belt life and provides a more consistent performance over the life of the belt.

- Pneumatically controlled rigid tensioning assembly adjusts and maintains belt tension with parallel movement for extended belt life.

Plow Grid Assembly

- Pneumatic actuator lifts or lowers entire plow assembly for easier cleaning, eliminating manually lifting each row of plows.

UHMW Polyethylene Plows

- Individually adjustable UHMW polyethylene plows are free floating but properly weighted to always maintain contact with the belt. More rows and more plows increase belt exposure to allow filtrate to escape.

One Piece Bearing Housing

- CMC utilizes Rilsan Nylon coated one-piece pillow block bearing housings with gasketed end cap. Self-aligning double-row spherical bearings with quadruple lip seals. All bearings provided on the Charter Machine Gravity Belt Thickener are guaranteed for the life of the equipment.

Belt Wash Station

- Stainless steel belt wash station, internal brush system with hand-wheel operated flush design.

Benefits

Maximum Performance

- Reduction of sludge volume by up to 90%

- Reduced load on downstream processes

- Improved performance and/or reduced size of downstream units

- 11+ rows of plows for increased throughput and improved thickening performance

Cost Effective

- Minimal installation expense

- Reduced hauling costs

- Low energy and polymer consumption

- Low or no wash water consumption

- Solid-block quadruple-sealed bearing cases reducing maintenance costs.

Simplified Operation

- The gravity deck is positioned at eye level for effortless adjustments and seamless operation.

- Pneumatic actuator lifts or lowers entire plow assembly for easier cleaning, eliminating manually lifting each row of plows.

- Vertically movable self-adjusting plows which can be replaced within seconds.

- Center-pivoting belt steering roll reduces uneven sludge belt stretching.

Design Flexibility

- Available in all sizes and models

Plug and Play

- Total System Responsibility

- CMC offers skid mounted systems that can be customized to meet any facility's needs. Our custom system designs can include GBT only or be a complete "plug and play" system combining any combination of sludge feed pump, compressor, booster pump, in-line mixer, polymer system, conveyors, and control panel. See our Skid-Mounted Systems page to discover the perfect combination of size and flexibility.

Applications

MUNICIPAL

| WASTEWATER / DRINKING WATER | |

|

|

|

|

INDUSTRIAL

|

|

|

|

AGRICULTURE

|

|

|

|

FOOD & BEVERAGE

|

|

|

|

OTHER

|

|

Video

Machine Drawings

Product Brochure

Related Products

Related Services

Image Gallery