Extractive and Process Industries

The Industrial Water Challenge: Balancing Productivity, Cost, and Environmental Impact

Modern industries face a complex challenge in managing water. While water is essential for production processes, high water usage translates to increased treatment costs, straining profitability. Furthermore, the resulting wastewater byproducts, such as those from pulp & paper production, pharmaceuticals, chemicals, plastics, and mining, pose a significant environmental and economic burden. These byproducts are expensive to store, transport, and dispose of improperly, and can also lead to environmental hazards. Fortunately, Charter's innovative sludge processing technologies can help industrial facilities manage these byproducts more efficiently and optimize their water use.

Market Focus: Specific Solutions for Specific Industries

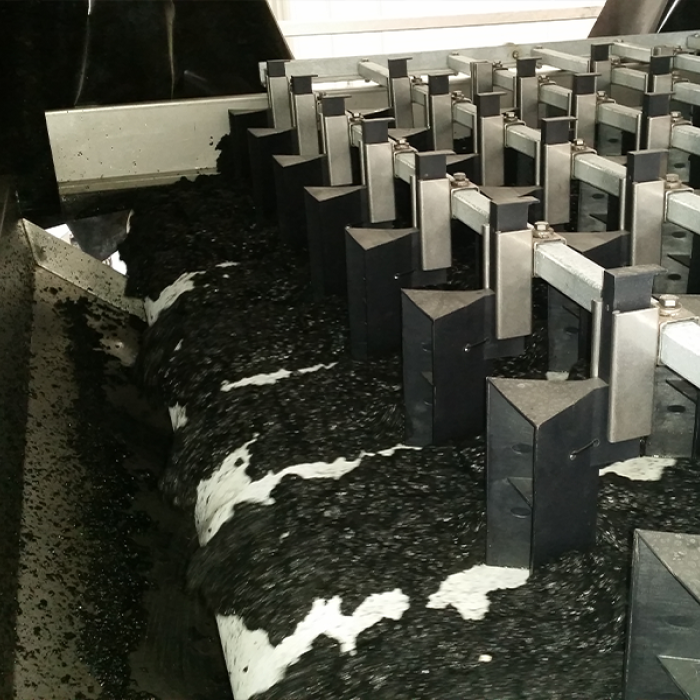

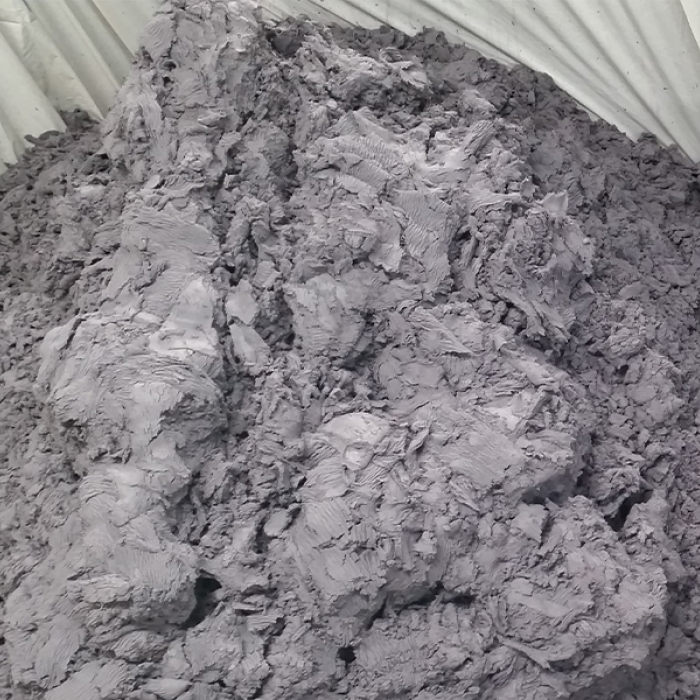

Unlike other fossil fuels, coal contains significant amounts of unusable materials. These impurities must be removed before, during, and after mining. The process generates large volumes of waste, including overburden (removed soil), processing leftovers such as coal refuse, and coal ash. One key challenge involves coal washing. Before burning for power generation, coal undergoes a washing process to remove impurities like rock and clay. This creates a watery slurry of fine coal particles. Traditionally, this "underflow" slurry is stored in large ponds, posing environmental risks, and taking up valuable space. Charter offers a range of dewatering solutions, from initial thickening to final stage drying, all designed to work independently or together for a fully customized process that maximizes cake dryness. This translates to lower storage costs, a smaller environmental footprint, and improved compliance with regulations regarding coal processing wastewater. Additionally, dewatered coal can be of higher quality for power generation, leading to increased efficiency.

Empowering Efficiency Across Industries

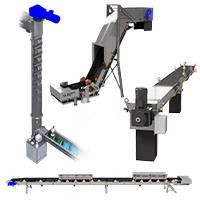

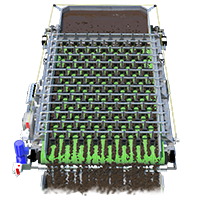

Charter's expertise extends beyond dewatering. We offer a comprehensive suite of material handling solutions, including custom-built conveyors. These versatile conveyors can handle a wide range of materials, from sticky and lumpy semi-solids to coarse dry materials, ensuring efficient transport throughout your entire production cycle, even in harsh industrial environments.

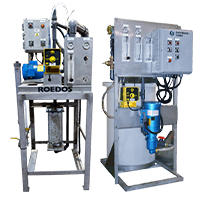

We understand that every industrial operation has unique needs. That's why we offer skid-mounted systems that can be customized to your specific requirements. These systems can include individual components or complete "plug and play" solutions with features like pumps, mixers, and control panels. With Charter, you can create a system that seamlessly integrates with your existing operation, optimizing efficiency and sustainability.

Typical Applications

- Pulp & Paper Wastes

- Chemical Sludges

- Coal Refuse

- Mining Concentrates

- Printed Circuit Board Sludges

- Asphalt and cement production

- Tannery Sludges

- Industrial Oil Sludge

- Drum, Truck and Tanker Wastes

- Dyes Inks and Pigments

- Fluoride Sludges

- Glue Wastes

- Paint Sludges

- Wood Treating Oils