Tower Regent Press

Every Little Bit Counts

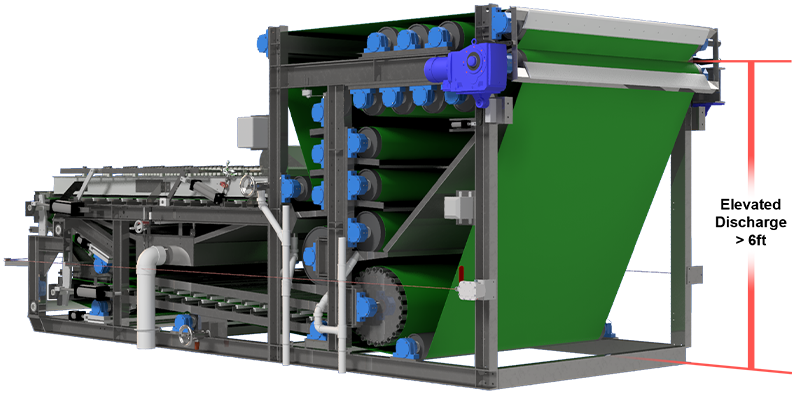

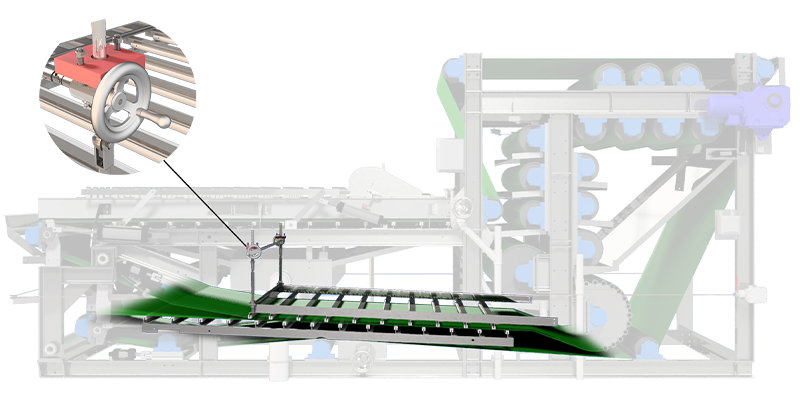

Our Tower Regent 15-Roll High-Solids Press is an enlarged version of the Tower Press. Seven additional rollers (15 total) provide more retention time, allowing for additional shearing and pressure. Depending on the solids processed, this could increase cake solids by 2 to 5 percent.

Product Data

Description

Our Tower Regent Press 15 Roll is an enlarged version of the Tower Press. Seven additional rollers (15 total) provide more retention time, allowing for additional shearing and pressure. Depending on the solids processed, this could increase cake solids by 2 to 5 percent.

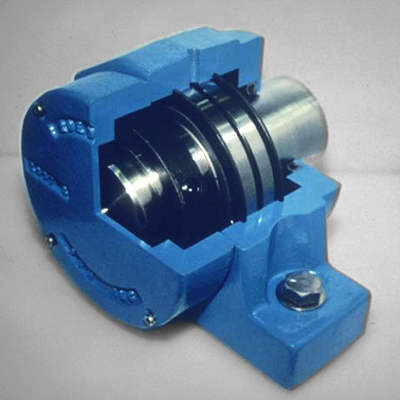

Like our standard Tower Press, the Regent models are equipped with 1-piece solid pillow block bearing housings, self-aligning double row spherical bearings, with a quadruple lip seal. The bearing housings are machined in-house for total quality control and coated with a 2-part epoxy base primer with 4 mil thickness and 2 finish coats of 2-part epoxy at 4 mil per coat dry film thickness.

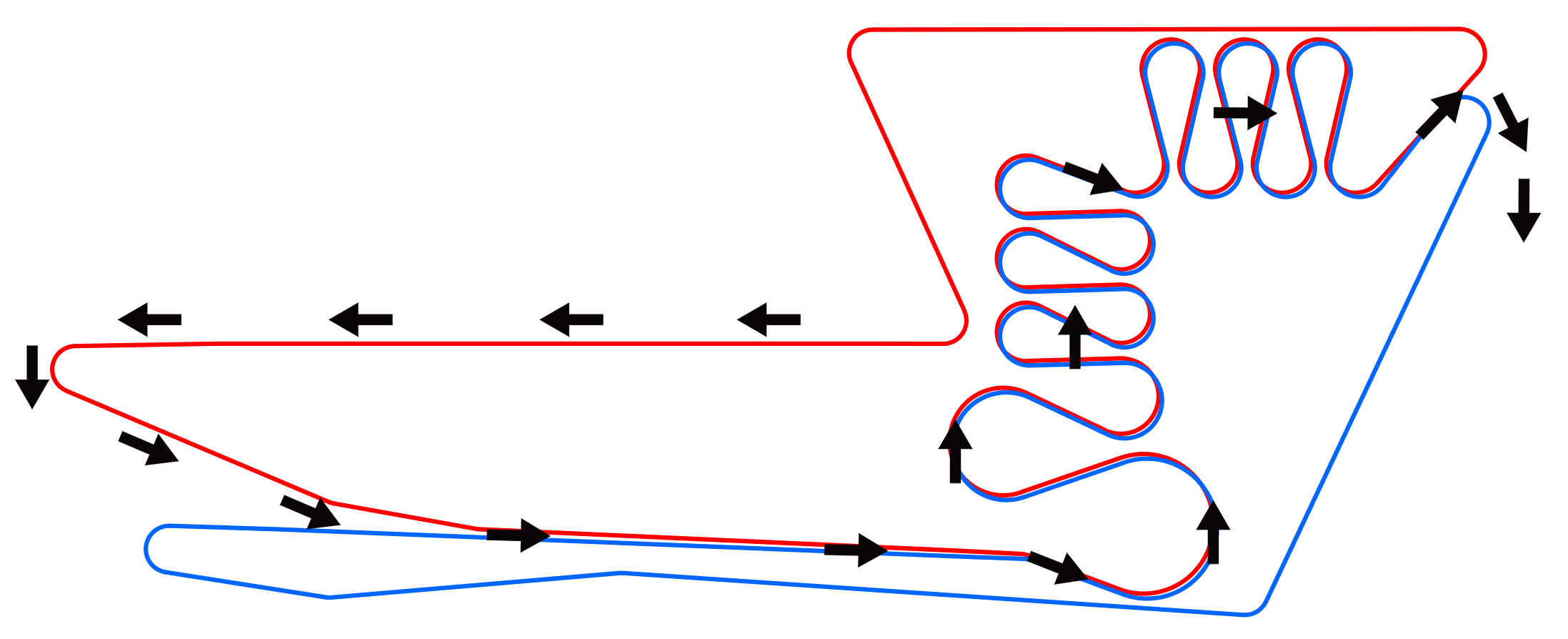

All Tower Regent Press models include the same user-friendly features found in our Tower Press, such as center pivot, adjustable wedge zone, filtrate recycling option, high discharge and our patented pneumatically operated doctor blade and plow lift designs.

Over the years, Tower Regent Press has evolved in direct response to operator suggestions that have made it a better and easier to operate dewatering system. Its innovative design is leaps and bounds ahead of the industry, resulting in high cake solids, improved capture rate and excellent throughput.

Forget the maze of platforms and catwalks. The Tower Regent Press boasts a revolutionary vertical design that eliminates the need for these costly add-ons. Its gravity deck sits conveniently at eye level, granting easy access for adjustments and visual monitoring. The elevated discharge allows for direct loading of cake, potentially bypassing conveyors altogether and simplifying your process. This translates to reduced complexity, lower energy consumption, and a lighter burden on your wallet.

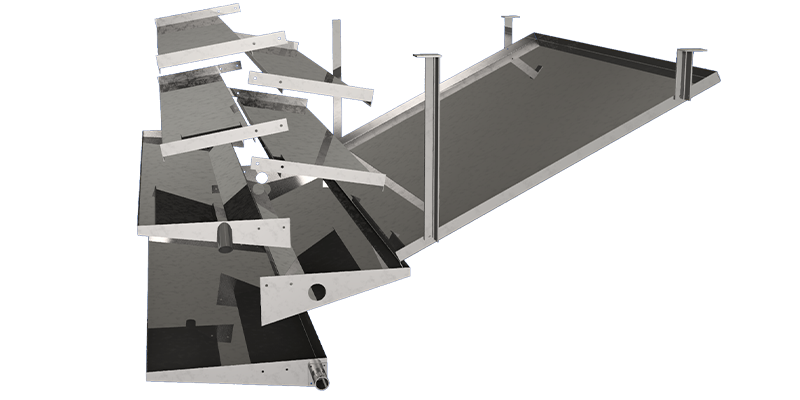

Vertically aligned pressure rollers assure maximum cake dryness to minimize hauling and land fill fees. The Charter Machine patented stainless steel drip pan design, positioned under each roller prevents re-wetting of the cake, keeping moisture content to a minimum.

Tower Regent Press units are also available in short deck versions where space is a premium.

TP07.5 Tower Press

Small Capacity, Big Capabilities: The TP07.5 Tower Press functions just like our Tower Press, but requires less space.

It allows smaller facilities that have the same problems as larger plants, to have the same center-pivot design, same vertical arrangement of rollers and same individual drip pans. All TP07.5 units are customized with a rotating gravity zone for smaller foot prints. This .7-meter unit is also available in our 8 roll Tower Press Model

Models

| MODEL | # ROLLS | DECK STYLE | OAL | PLI | BELT WIDTH |

|---|---|---|---|---|---|

| TP07.5 | 15 | - | 9'-11 ½" | 0.7 M | |

| TP12.51S | 15 | SHORT | 50 | 1.2 M | |

| TP12.53S | 15 | LONG | 23'-½" | 50 | 1.2 M |

| TP12.53SH | 15 | LONG | 23'-½" | 70 | 1.2 M |

| TP17.51S | 15 | SHORT | 50 | 1.7 M | |

| TP17.53S | 15 | LONG | 23'-½" | 50 | 1.7 M |

| TP17.53SH | 15 | LONG | 23'-½" | 70 | 1.7 M |

| TP22.52S | 15 | SHORT | 19'-⅝" | 50 | 2.2 M |

| TP22.52SH | 15 | SHORT | 19'-⅝" | 70 | 2.2 M |

| TP22.54S | 15 | LONG | 23'-½" | 50 | 2.2 M |

| TP22.54SH | 15 | LONG | 23'-½" | 70 | 2.2 M |

Features

All Tower Regent Press models include the same user-friendly features found in our Tower Press, such as; center pivot, adjustable wedge zone, filtrate recycling option, high discharge and our patented pneumatically operated doctor blade and plow lift designs.

All Tower Regent Press models include the same user-friendly features found in our Tower Press, such as; center pivot, adjustable wedge zone, filtrate recycling option, high discharge and our patented pneumatically operated doctor blade and plow lift designs.

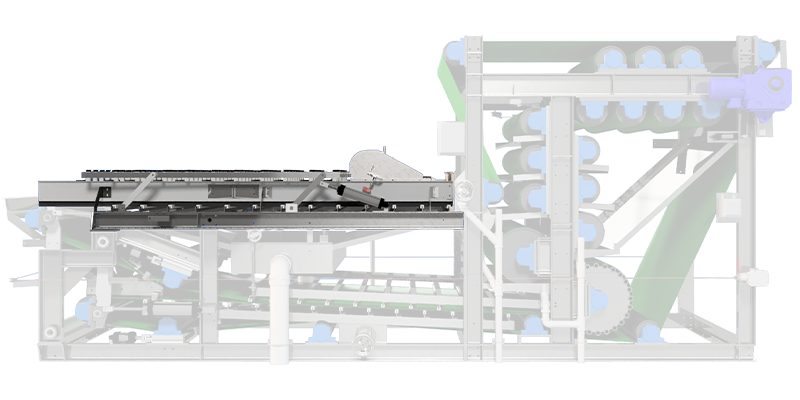

Eye level Gravity Deck

The gravity deck is positioned at eye level, allowing for accurate visual adjustments without the costly addition of catwalks, steps, or risers around the Tower Press.

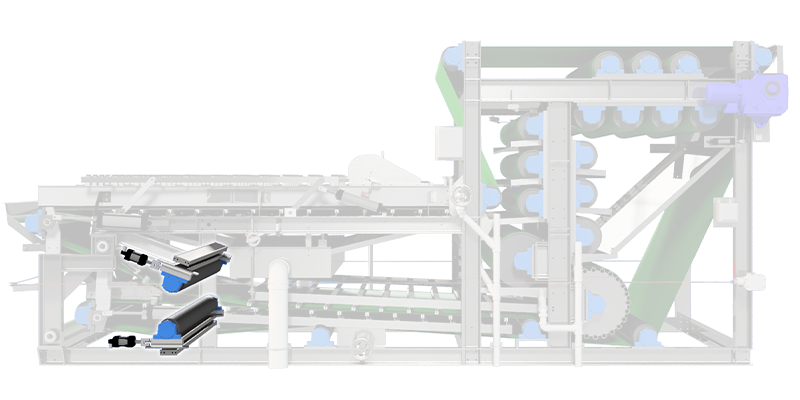

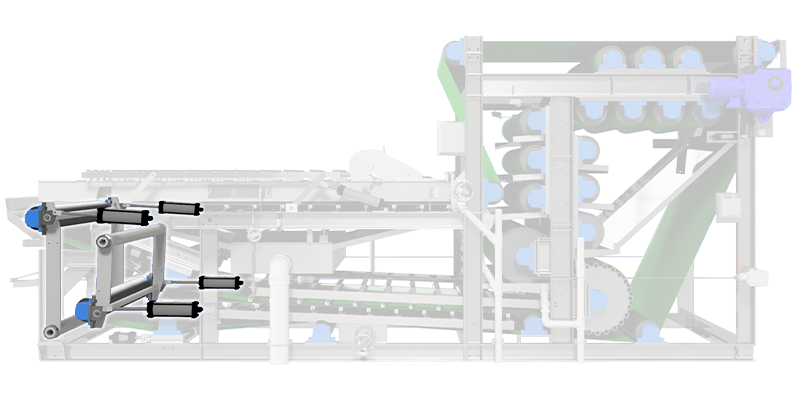

Center Pivot Tracking

The Tower Press features a revolutionary center pivot design that is user friendly and easier on belts. The unique center pivot design improves belt alignment by adjusting both sides of the belt simultaneously for quicker performance over the life of the belt.

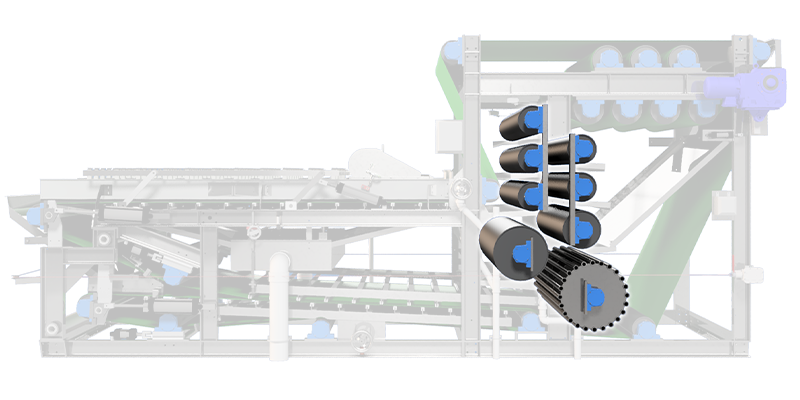

Stacked Pressure Rollers

The improved design begins with the pressure rollers. With Tower Press, the pressure rollers are aligned vertically. This guarantees maximum high cake dryness, which in turn minimizes hauling costs and landfill fees.

Individual Drain Pans

Non-corroding, stainless steel drain pans are positioned at each roller to prevent any rewetting of the preceding sludge cake.

Elevated Discharge

Tower Press features an elevated discharge that’s more than 6-feet off the floor, making it simpler to add ancillary equipment for further processing.

Pneumatic Belt Tensioning

Our pneumatic Belt Tensioning always maintains consistent and even tension on the belt for smooth operation and long belt life.

One Piece Bearings

Tower Press uses one-piece pillow-block bearings with a gasketed end-cap and self-aligning double-row spherical-roller and quadruple lips. The bearing housings are machined in-house for total quality control and coated with a 2-part epoxy base primer with 4 mil thickness and 2 finish coats of 2-part epoxy at 4 mil per coat dry film thickness.

|

Wedge Zone - Fully adjustable wedge zone.

Filtrate Recycling Option

Benefits

Simplified Operation

- The gravity deck is positioned at eye level for effortless adjustments and seamless operation.

Maximum Dryness

- 15 rolls provide more retention time, allowing for additional shearing and pressure. Depending on the solids processed, this could increase cake solids by 2 to 5 percent.

- Vertically aligned pressure rollers assure maximum cake dryness.

- Charter Machine patented stainless steel drip pan design, positioned under each roller prevents re-wetting of the cake, keeping moisture content to a minimum.

Reduced Costs

- The entire dewatering process may be observed from ground level, reducing plant design and construction costs. No platforms, catwalks, or complex conveyors needed.

- The Tower Press easy maintenance, “hands-off” design reduces manpower hours and therefore overall operations costs.

- Maximum cake dryness achieved from our Tower Presses results in hauling and land fill fee savings.

Enhanced Efficiency, Effortless Automation

- Doctor blades and plows are pneumatically actuated for easier operation and cleaning. Only the Tower Press offers this exclusive feature.

- Center pivot tracking rolls eliminate one-side belt stretch and deliver quicker response to belt misalignment.

- Rigid tensioning assembly adjusts belt tensions with parallel movement.

- Optional filtrate recycling eliminates the need to use plant water to clean filter belts.

Improved Safety

- Easy access minimizes fall risks.

Multiple Sizes

- Tower Regent Press is sized to fit your needs. It’s available with a 0.7, 1.2, 1.7 or 2.2-meter belt sludge dewatering equipment. Say goodbye to one-size-fits-all at Charter. We tailor our designs to fit your project like a glove.

Mix and Match, Plug and Play

- CMC offers skid mounted systems that can be customized to meet any facility's needs. Our sump/skid systems can include the belt filter press only or be a complete "plug and play" system combining any combination of sludge feed pump, compressor, booster pump, in-line mixer, polymer system, conveyors, and control panel. See our Skid-Mounted Systems page to discover the perfect combination of size and flexibility.

Video

Machine Drawings

Product Brochure

Related Products

Related Services

Image Gallery