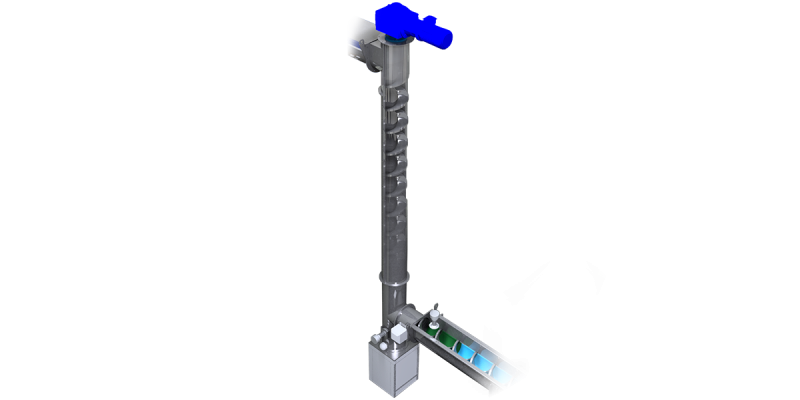

Vertical Screw Conveyor

Screw Up Your Way to Efficiency

Charter’s Vertical Screw Conveyors provide a superior method for lifting a wide range of bulk materials. Their space-saving design ensures they can be incorporated into virtually any plant layout.

Product Data

Description

Charter’s Vertical screw conveyors provide a superior method for lifting a wide range of bulk materials. Their space-saving design ensures they can be incorporated into virtually any plant layout. Furthermore, minimal moving parts contribute to their cost-effectiveness and reliability, making them a trustworthy choice for any bulk material handling operation.

CMC takes pride in customizing its vertical screw conveyor designs to cater to the unique needs of a broad spectrum of industries. Whether it's chemical processing, mineral refinement, food production, pulp and paper manufacturing, or wastewater treatment, we have the perfect solution. Notably, our innovative shaftless vertical screw conveyor design has become a mainstay in wastewater treatment facilities. It efficiently elevates dewatered biosolids, seamlessly integrated with our turnkey custom dewatering systems for a streamlined sludge processing experience. The inlet sections can be positioned either offset to the side or in-line for optimal integration into your existing layout. To ensure maximum efficiency, we require pairing them with horizontal feed conveyors that precisely meter bulk materials directly into the vertical unit's inlet.

CMC’s dedicated Engineering Sales professionals are here to guide you. They'll help you identify the ideal vertical inlet configuration to perfectly align with the specific demands of your vertical conveying and production needs.

Benefits

Versatile Material Handling

- Handles a wide range of materials, from free-flowing dry powders to slightly sluggish semi-fluids.

High Capacity

- Can handle bulk materials at rates up to 6,000 cubic feet per hour, making them suitable for large-scale operations.

Efficient Elevation

- Elevates materials up to 30 feet without requiring internal bearings, simplifying design and potentially reducing maintenance costs.

Leak-Proof Operation

- The totally enclosed design ensures dust and vapor tight operation, minimizing environmental contamination and promoting a cleaner, safer work environment.

Applications

MUNICIPAL

| WASTEWATER / DRINKING WATER | |

|

|

|

|

INDUSTRIAL

|

|

|

|

AGRICULTURE

|

|

|

|

FOOD & BEVERAGE

|

|

|

|

OTHER

|

|

Video

Product Brochure

Related Products

Related Services

Image Gallery