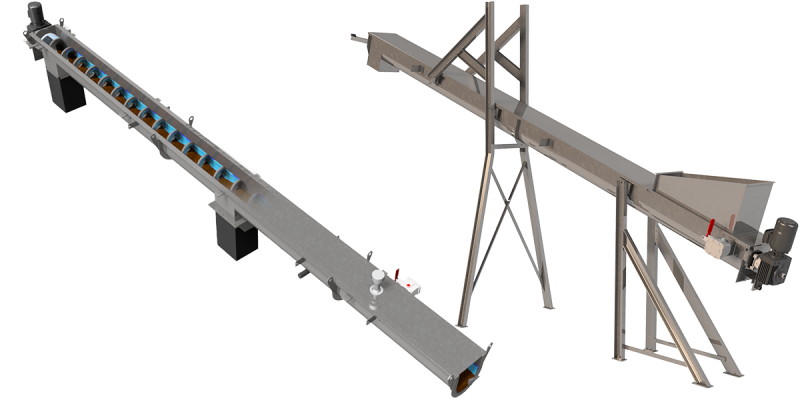

Shaftless Screw Conveyor

Simple Design, Smooth Operation

The Shaftless Screw Conveyor is the perfect solution for moving dry and semi-solids. The simplistic, pipeless design makes it a great candidate for moving scrap woods, scrap metals, compost, pulp, and wastewater products.

Product Data

Description

The Shaftless Screw Conveyor is the perfect solution for moving dry and semi-solids. The simplistic, pipeless design makes it a great candidate for moving scrap woods, scrap metals, compost, pulp, and wastewater products. Since Shaftless Screw Conveyors utilize less parts, the overall maintenance costs less time and money. Its simplistic design allows for higher trough loading and low RPM’s, maximizing the amount of material it can convey.

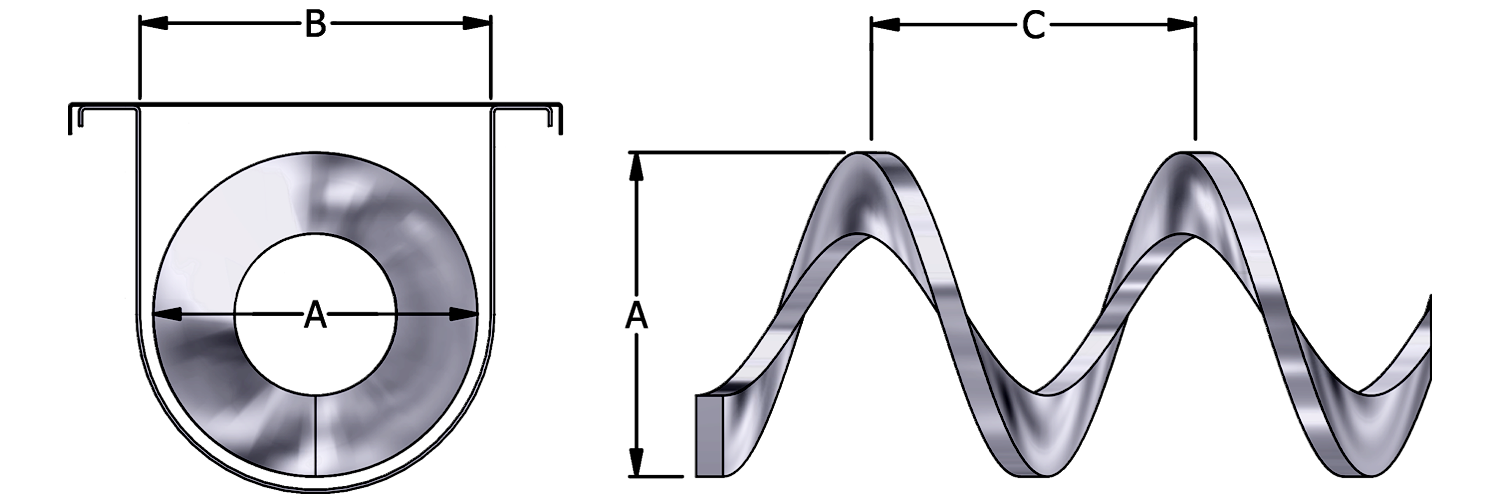

General Specifications

| A Dia. | B Inside | C Pitch | 45% SludgeTrough Loading | Max RPM | ||||

|---|---|---|---|---|---|---|---|---|

| CFH* Full Pitch | Lbs/Hr | Dry Cake Quality (***Lbs/ds/hr) | ||||||

| 15% | 20% | 30% | ||||||

| 6 | 7 | 6 | 65 | 3,975 | 465 | 629 | 969 | 25 |

| 9 | 10 | 9 | 224 | 13,418 | 1571 | 2123 | 3273 | 25 |

| 10 | 11 | 10 | 307 | 18,406 | 2155 | 2912 | 4489 | 25 |

| 12 | 13 | 12 | 530 | 31,806 | 3724 | 5032 | 7758 | 25 |

| 14 | 15 | 14 | 842 | 50,507 | 5914 | 7992 | 12318 | 25 |

| 16 | 17 | 16 | 1,244 | 75,393 | 8828 | 11929 | 18388 | 25 |

Data table is calculated for horizontal screw conveyor orientation.

*CFH = Cubic feet per hour.

** ALL DIMENSIONS SHOWN IN INCHES.

***Lbs/ds/hr = Pounds of Dry Cake per hour.

Features

Continuous Flight

- Lowers maintenance/operation costs by eliminating hanger bearings.

- Continuous flight eliminates hangers - reduces maintenance cost.

Horizontal, Inclined or Vertical Orientation

- Design flexibility

Blind End Plate

- Lowers maintenance/operation costs by eliminating tail seals tail bearings.

Shaftless Screw

- No center pipe/shaft - Eliminate buildup on pipe, increases screw capacity, lower maintenance/operation costs.

- Higher trough loading (45%) and low RPM’s, maximizing the amount of material it can convey.

Optional Slide Gate

- Easily control discharge flow at one or multiple points.

Wear Liner

- Wear liners - reduces maintenance cost and easy to replace.

Optional Rubber Discharge Skirting

- Abrasion resistant

Enclosed Trough or Tube

- Reduces dust and/or spillage.

- Significant Odor Reduction.

Optional Insulated Troughs and Covers

- Winter-proof

Benefits

- Ideal for viscous, sticky, wet and lumpy materials

- longer life

- lower maintenance/operation costs

- increases screw capacity

Applications

MUNICIPAL

| WASTEWATER / DRINKING WATER | |

|

|

|

|

INDUSTRIAL

|

|

|

|

AGRICULTURE

|

|

|

|

FOOD & BEVERAGE

|

|

|

|

OTHER

|

|

Video

Product Brochure

Related Products

Related Services

Image Gallery