Electro-Osmosis Dehydration Cost-Effectively Increases Solids Content

Technologies like belt presses, screw presses, rotary fan presses and centrifuges dewater biosolids and water treatment sludges effectively.

But what if circumstances require material with higher solids content than those devices can provide? For example, what if a landfill suddenly requires material at 40% solids instead of 20%? Or what if the cost of hauling material at 20% solids becomes too high to sustain?

One option is to add a thermal dryer to the process, essentially boiling off some of the excess water. Another option, new to the U.S., is an electro-osmosis dehydrator, a technology that uses electric fields to pull the water out of the material.

That’s the ELODE system, distributed by Charter Machine Co. It removes water at much lower cost than thermal drying. The system comes in a compact footprint and is easily installed downstream of a facility’s mechanical dewatering process.

How it works

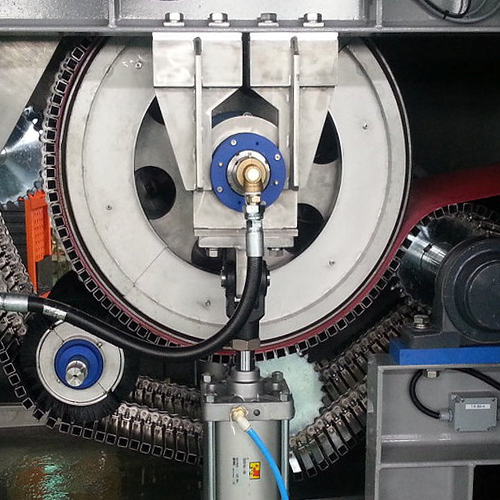

The ELODE system works by feeding dewatered cake into the unit, which includes a distribution chamber where it’s flattened onto a belt. Tension holds the material in contact with the drum to keep it moving. At that point, a DC current causes water to be released and in a few minutes the solids content is doubled, according to Charter Machine Director of Sales Christopher Boyd.

“If you’re paying $60 or $70 a wet ton to landfill cake solids, you can cut your cost in half by using our equipment. After paying for the equipment and the electricity, there is a very short payback. For large cities paying high rates for landfilling, it can be very attractive.”

Charter Machine Co. is a manufacturer of machinery for the wastewater and biosolids management industry. The company’s decades of commitment to serving this industry enables it to build and maintain mutually beneficial customer relationships for the betterment of water conditions in our environment.