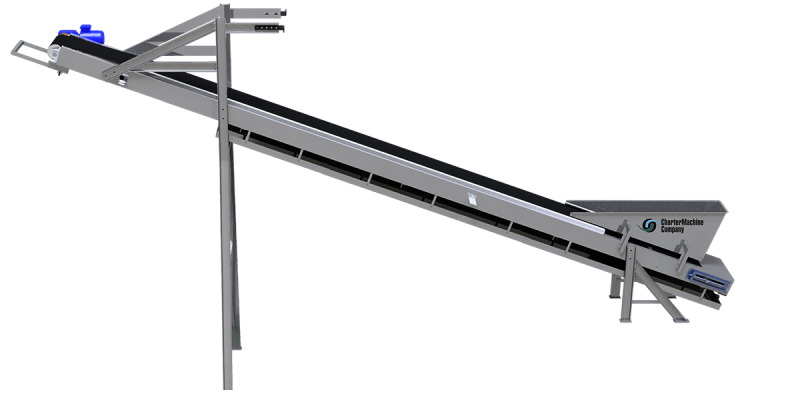

Slider Belt Conveyor

Your shortcut to smooth handling

Charter's Slider Conveyor belts glide on cost-effective, easily replaceable UHMW slats instead of traditional idler rollers. This simple yet versatile design makes them an economical alternative to more complex conveyor options.

Product Data

Description

Charter’s Slider Conveyors typically utilize long-lasting, interwoven PVC belts driven by friction on the drive pulley. These belts, known as "Free Slide", feature a durable PVC top and a bare polyester bottom, proven for extended wear, high performance, and smooth material handling. The minimal friction of the bare surface reduces energy consumption. Additionally, the belts glide on cost-effective, easily replaceable UHMW slats instead of traditional idler rollers. This simple yet versatile design makes them a cost-effective alternative to more complex conveyor systems, handling materials like fertilizers, chemicals, and bulk materials efficiently. Ideal for short-run distances.

Our custom-designed belt conveyors are built to handle your unique application, following industry best practices. We factor in bulk material characteristics, feed rate, loading needs, temperature and more for a tailored solution.

Features

Wear Pad UHMW Belt Supports

- Wear pads are a fraction of the cost compared to traditional idlers, saving you money upfront and over time.

- Our wear pads are easy to replace, minimizing downtime and keeping your operation running smoothly.

- Consistent support along the entire troughing section, reducing belt stress and extending its lifespan.

Emergency Stop System

- OSHA-Compliant Cable Pull Emergency Stop accessible from all sides for enhanced safety.

Skirting

- Our expertly engineered skirting systems effectively contain material and prevent spillage, saving you money and resources.

- Improved workplace safety: Eliminate the risk of dust inhalation and material spills with our reliable and secure skirting solutions.

- Reduce environmental impact

- Our most popular style: Available in minimum 14-gauge type 304 corrosion-resistant stainless steel skirting with rubber seal. Ideal for wet, semi-dry applications.

- Multiple styles available to meet your unique applications. (rubber belt style, steel only, skirtboard, etc.)

Scraper Blade

- Counterweighted scraper blade removes material carryback, preventing buildup and ensuring smooth operation.

- Replaceable blade design allows for quick and easy maintenance, reducing downtime and keeping your operation running efficiently.

- By preventing material buildup, our scraper blade helps to extend the lifespan of your conveyor belt, saving you money in the long run.

Drip Pans

- Capture leaks and prevent drips: Our non-corrosive stainless steel drip pans effectively contain spills and channel fluids to a designated discharge point.

Conveyor Frame and Supports

- Corrosion-resistant: Galvanized coating with a minimum 5 mil thickness offers long-lasting protection against harsh environments.

- Heavy-duty carbon steel construction: Ensures exceptional strength and stability to handle even the most demanding applications. Other materials available per your application.

Optional Zero speed switch

- Provides cost-effect protection

- Rugged, low maintenance suitable for tough environments

Benefits

Ideal for short-run distances

Economical

- Wear pads - fraction of the cost in comparison to Idlers.

- "Free Slide" PVC belting features a bare surface that significantly reduces friction, leading to improved energy efficiency.

Design Flexibility

- Flat, cleated or sidewall belt styles

- Incline and horizontal orientations

Enhanced Safety

- Cable Pull Emergency Stop allows for quick and easy conveyor stoppage from any direction in case of emergencies.

- Our Material Containment Skirting reduces the risk of dust inhalation and material spills.

- Drip Pans and Covers effectively manage moisture runoff and shield the conveyor from external elements, promoting overall system protection.

- Non-Corrosive Construction

Seamless Operation

- Counterweighted scraper blade removes material carryback, preventing buildup and ensuring smooth operation.

Applications

MUNICIPAL

| WASTEWATER / DRINKING WATER | |

|

|

|

|

INDUSTRIAL

|

|

|

|

AGRICULTURE

|

|

|

|

FOOD & BEVERAGE

|

|

|

|

OTHER

|

|

Video

Product Brochure

Related Products

Related Services

Image Gallery