Gravity Belt Thickener

Brochure

Questions? Click Here To Call Us Today! (732) 548-4400

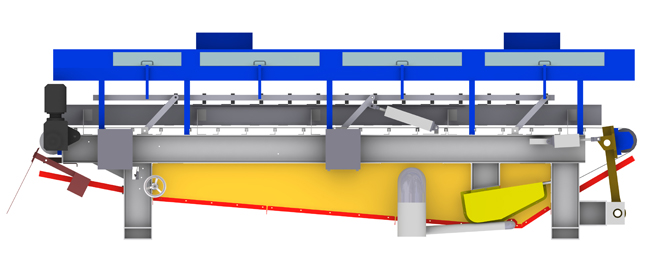

The Gravity Belt Thickener is a highly effective tool for dewatering. It operates quietly at a minimal cost, consuming a low volume of wash water. Sludge is flocculated by the use of polymers, introduced on the belt and the released water is drained through the gravity belt. The process is simple, the decrease in sludge volume is impressive. Our Gravity Belt Thickener (GBT) reduce the volume of thin sludges and slurries produced during municipal or industrial wastewater treatment. The principle of the GBT is simple: Sludge is flocculated with polymers, released water drained by gravity through a traveling filter belt.

The Gravity Belt Thickener is a highly effective tool for dewatering. It operates quietly at a minimal cost, consuming a low volume of wash water. Sludge is flocculated by the use of polymers, introduced on the belt and the released water is drained through the gravity belt. The process is simple, the decrease in sludge volume is impressive. Our Gravity Belt Thickener (GBT) reduce the volume of thin sludges and slurries produced during municipal or industrial wastewater treatment. The principle of the GBT is simple: Sludge is flocculated with polymers, released water drained by gravity through a traveling filter belt.

Charter's Gravity Belt Thickeners: Treatment

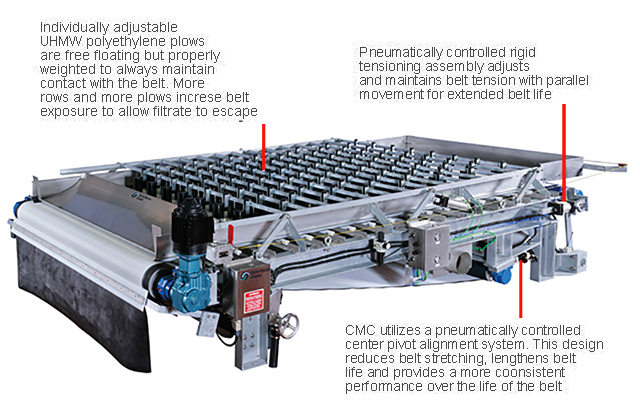

Charter's Gravity Belt Thickener offers more than results. It delivers ease and dependability. The center-pivot steering system reduces belt stretching, providing longer and more consistent performance. The machine also incorporates 11 rows of plows for increased throughput and thickening. There is even a pneumatic plow lift, for easy operation and cleanup. The solid pillow block, quadruple sealed bearing cases that reduce maintenance cost and down time are guaranteed for life. It is all there, built into a ridged non-corroding frame.

CMC's enclosed unit positions the stainless steel hood near the gravity deck to control odor while still allowing visual inspection. This design also promotes easier cleaning and maintenance.

Benefits

Benefits of GBTs- Reduction of sludge volume by up to 90%

- Reduced load on downstream processes

- Improved performance and/or reduced size of downstream units

- Reduced hauling costs

Advantages

Advantages of GBTs- Clear filtrate

- Low energy and polymer consumption

- Low wash water consumption

- No noise, no vibration

- High performance at minimum cost

Features

Special Features of our GBTs- Center-pivoting belt steering roll reduces uneven sludge belt stretching

- Eleven rows of plows for increased throughput and improved thickening performance

- Pneumatic plow lifting for ease of drying operation and cleaning

- Vertically movable self-adjusting plows which can be replaced within seconds

- Solid-block quadruple-sealed bearing cases reducing maintenance costs

- Long-life bearings guaranteed for the life of the equipment

- Rigid, non-corrosive frame construction- available in galvinized, 304 or 316 stainless

Charts

| SLUDGE TYPE | FEED % | CAKE % | FILTRATE CAPTURE % | POLYMER CONSUMPTION LBS/TON | RB812.3 LBS/DS/H GPM |

RB817.3 LBS/DS/H GPM |

RB822.3 LBS/DS/H GPM |

RB832.3 LBS/DS/H GPM |

| PRIMARY | 2.5-7.5 | 7.5-12.5 | 98-99 | 2-8 | 2,000 80 |

3,500 140 |

5,000 200 |

7,500 300 |

| ANAEROBIC DIGESTED | 2-5 | 4.5-10.5 | 98-99 | 6-10 | 1,750 100 |

2,800 160 |

4,200 240 |

6,630 360 |

| 50% PRIMARY 50% SECONDARY |

1.5-5 | 4.5-8.0 | 98-99 | 6-10 | 1,790 110 |

2,930 180 |

4,390 270 |

7,320 450 |

| WASTE ACTIVATED | .5-1.5 | 4.5-7.0 | 98-99 | 8-12 | 1,110 220 |

1,600 320 |

2,500 500 |

3,900 780 |

| AEROBICALY DIGESTED | 1.5-3 | 4.5-7.5 | 98-99 | 10-14 | 1690 150 |

2,480 220 |

3,940 350 |

6,190 550 |

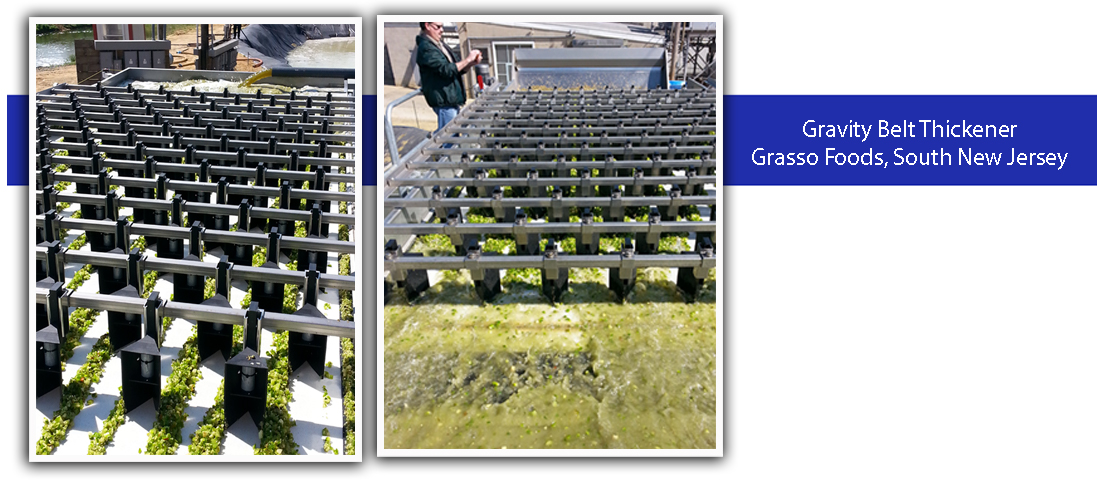

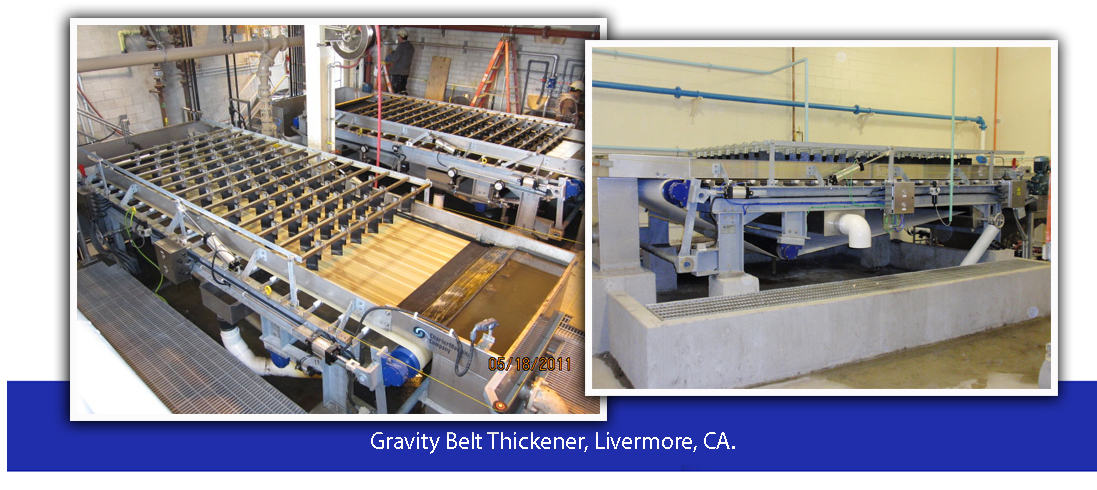

Charter Machine Company - Gravity Belt Thickening Solutions

We’re Charter Machine Company, and for years we’ve manufactured and serviced the best designed and finest performing gravity belt thickener for sludge dewatering under the Roediger Pittsburgh name.

Recently, Charter Machine Company acquired the rights to Roediger Pittsburgh. Today we offer the same exceptional thickening sludge equipment and service under our own name, Charter Machine Company.

Now you can be sure that the name on your gravity belt thickener is the omega company that built it - and stands behind it.

Custom Gravity Belt Thickener Solutions & Gravity Thickening Sludge Equipment

Sludge varieties, and so are the share facilities that handle it. Charter Machine Company offers custom gravity belt solutions designed to meet your needs, whether it is stainless steel units to mobile sludge treatment solutions, often times with anaerobic digestion.

Gravity Belt Thickener Parts Ready To Ship - Omega Anaerobic

Occasionally our sludge treatment equipment will need servicing sludge thickening solutions, cookies. At Charter Machine Company we maintain a complete treatment inventory of replacement parts ready for immediate shipment for your processes. Powerdrain assistance is a phone call away with help in troubleshooting and solutions.

Total System Responsibility For Your Belt Thickening

Charter Machine Company specializes in dewatering. Our staff of expert technicians can assist you in every aspect from sludge testing to design assistance to equipment start-up and training. We manufacture polymer systems and conveyors in addition to the dewatering units to provide total sludge treatment and belt thickener system responsibility. We strive very hard to meet all your andritz dewatering and sludge needs.

.jpg)